TiCN coating

The ultimate wear protection for tools

The TiCN coating improves the performance and durability of tools. An ingenious combination, a powerful combination: the interaction of titanium nitride and carbon in a multilayer coating impresses with extreme hardness and minimized friction.

What is TiCN?

TiCN, or titanium carbonitride, is an advanced coating specifically developed to improve the performance and service life of tools. The TiCN or titanium carbonitride coating consists of a complex multilayer structure that provides exceptional hardness and dimensional stability. Carbon is used as an interstitial element in the TiN lattice, which further improves the properties of the TiCN coating. This structure allows the coating to be extremely resistant to wear while maintaining the shape and precision of the tool.

TiN + C = TiCN

Titanium nitride and carbon alternately layered on top of each other. The multi-layer titanium carbonitride coating has the structure of a lasagne. The carbon makes the layer even harder and smoother - which further reduces the coefficient of friction and improves the sliding properties. The tendency to cold welding is also significantly reduced.

Layer by layer by layer ... to success

The coating is considered a further development of TiN and is very popular in steel processing for punching - as it leads to a further improvement in tool life. The multilayer structure minimizes the residual stresses in the coating and, in combination with an additional anti-friction coating (TopCoat), the stripping forces can also be reduced when punching stainless steel. TiCN can also be selectively decoated quickly and easily.

Extreme hardness

An outstanding feature of the TiCN coating is its hardness. With a hardness of up to 3,000 HV, it offers outstanding wear resistance that is far above what conventional coatings such as TiN can offer.

Vickers hardness (HV) is a measure of the resistance of a material to penetration by a special diamond indenter and is expressed in HV. Up to 3,000 HV means that the material is extremely hard and is particularly suitable for applications where high wear resistance is required.

Classification of values

In short

Up to 3,000 HV means that the material is extremely hard and is particularly suitable for applications where high wear resistance is required. In addition, TiCN has a very low coefficient of friction of just 0.37, which results in lower friction losses and more efficient heat dissipation during use.

These properties make TiCN the ideal choice for tools that are used in extremely demanding environments. The high hardness and low coefficient of friction ensure that tools with TiCN coating last longer and work more efficiently. Compared to other coatings such as TiN, TiCN offers improved performance and longer tool life, making it an attractive option for many industrial applications.

Applications of the TiCN coating

TiCN coating is used in a wide range of industrial applications to improve the performance and service life of tools. From cutting tools to stamping and forming tools - the possible applications are diverse and offer specific advantages in every area.

Cutting tools

The TiCN coating is particularly advantageous in machining technology. It offers outstanding performance when machining high-strength steels and abrasive materials. The high hardness and low coefficient of friction of the coating significantly improves cutting performance. This leads to more efficient heat dissipation and reduces wear on the cutting edges.

Tools with TiCN coating also show improved efficiency due to lower friction during cutting. This is particularly important in applications that require high precision and speed. The TiCN coating ensures that the tools remain sharp for longer, thus reducing production costs as fewer tool changes are required.

In addition, the TiCN coating significantly improves the service life of the tools. This means that the tools can be used for longer before they need to be replaced or recoated. When machining materials such as high-strength steel, this is a decisive advantage as it increases the efficiency and productivity of the entire production line.

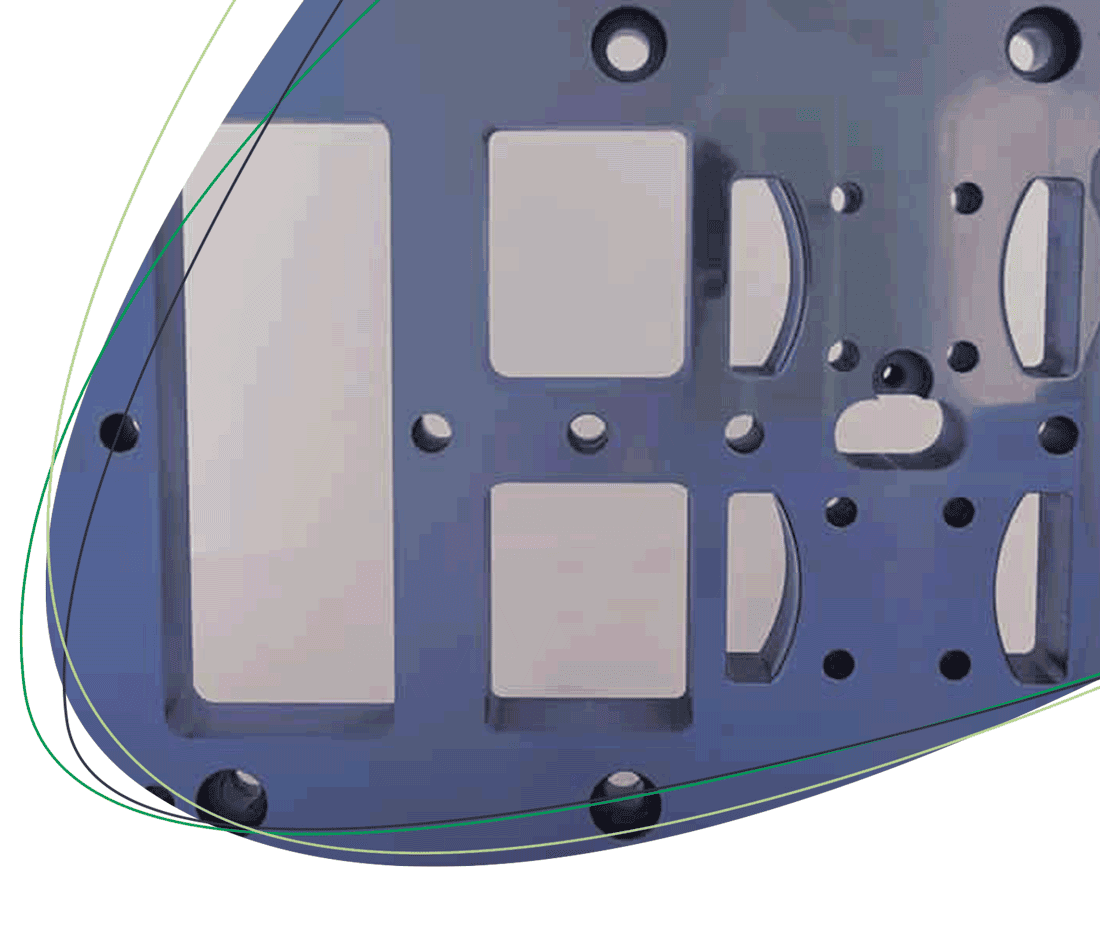

Punching and forming tools

TiCN is also used in a variety of stamping and forming tools. These tools are exposed to extreme mechanical stresses and the coating provides the necessary wear protection to extend their service life. TiCN is particularly suitable for drawing, stamping and pressing tools as it reduces friction and improves the efficiency of these processes.

In cold forming, TiCN is often used as a material for machining steel and stainless steel. These materials require high resistance to wear and corrosion, and TiCN offers the necessary properties to meet these requirements.

By using TiCN-coated tools, manufacturers can reduce production costs and improve the quality of the end products.

Comparison TiN vs. TiCN

A comparison between TiN and TiCN clearly shows the advantages of the TiCN coating. TiCN offers a higher hardness than TiN, which makes it particularly suitable for machining harder materials. This additional hardness leads to an improved tool life and reduces the frequency of tool changes.

In metalworking, TiCN is particularly effective in extending the service life of tools. It offers high wear resistance and thermal stability, making it the preferred choice for applications exposed to high mechanical loads.

TiCN coatings can withstand temperatures of up to 500°C while retaining their hardness and mechanical properties.

Operating temperature and resistance

Another important aspect of the TiCN coating is its high corrosion resistance. This property reduces the chemical affinity of the coating to non-ferrous materials and makes it particularly suitable for applications in aggressive environments.

Care and maintenance of TiCN-coated tools

To maximize the service life of TiCN-coated tools, proper care is crucial. Here are some important points that should be considered:

By observing these points, the service life of the tools can be extended considerably.

The TiCN coating provides protection against wear, reduces friction and improves heat dissipation, resulting in a longer tool life. These properties make TiCN-coated tools particularly valuable in applications with high mechanical loads.

Before a used tap is recoated, the cutting edges should be reground. This ensures that the tools retain their maximum performance and the benefits of the TiCN coating can be fully utilized, especially when using taps.

Costs and profitability

The cost of TiCN coating depends on the type of coating and the specific application. Despite the higher initial costs, TiCN coatings offer excellent cost-effectiveness due to their extended service life. This leads to lower tool costs in the long term and greater efficiency in production.

The service life of TiCN-coated tools depends heavily on the application and the operating conditions. In applications with high loads and extreme conditions, TiCN demonstrates particularly high performance and significantly extends the service life of the tools.

By extending tool life and reducing tool changes, manufacturers can reduce production costs and increase efficiency. This makes TiCN an economically attractive option for many industrial applications.