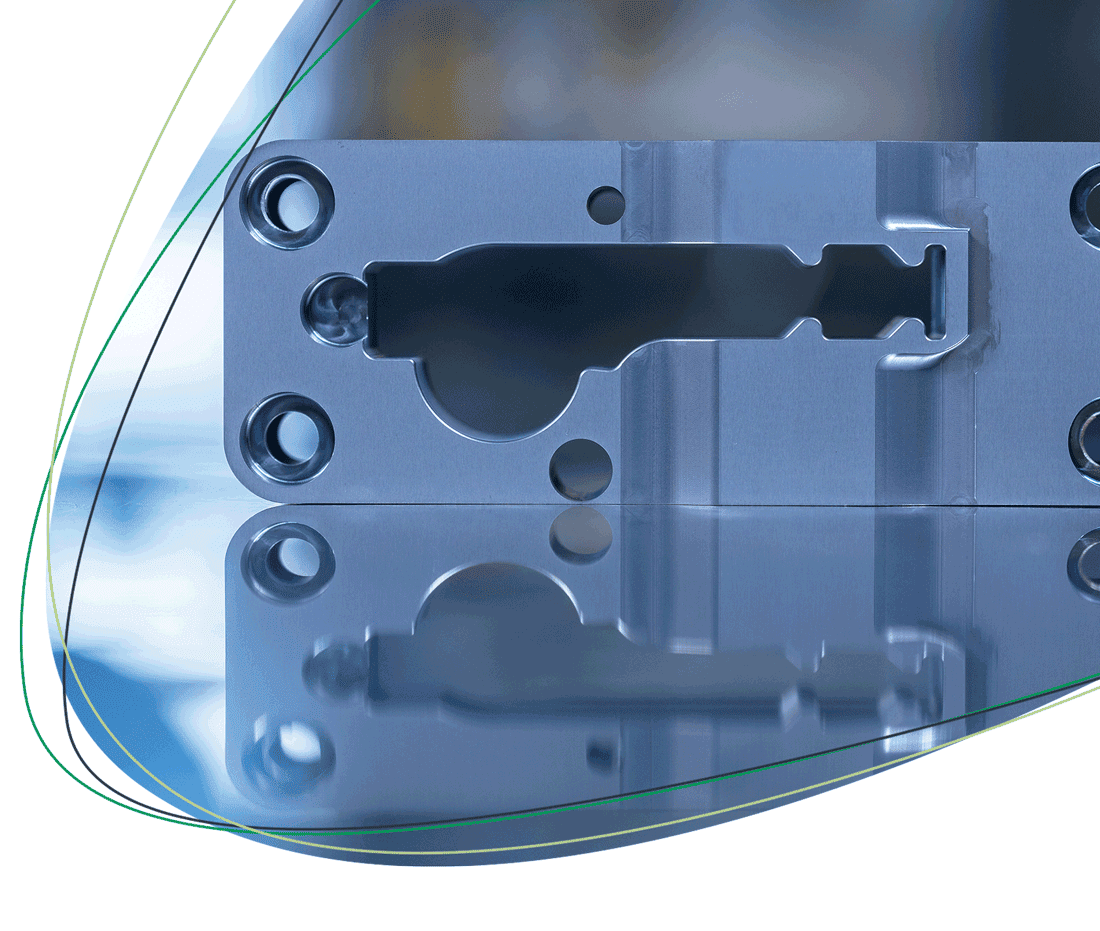

Applications

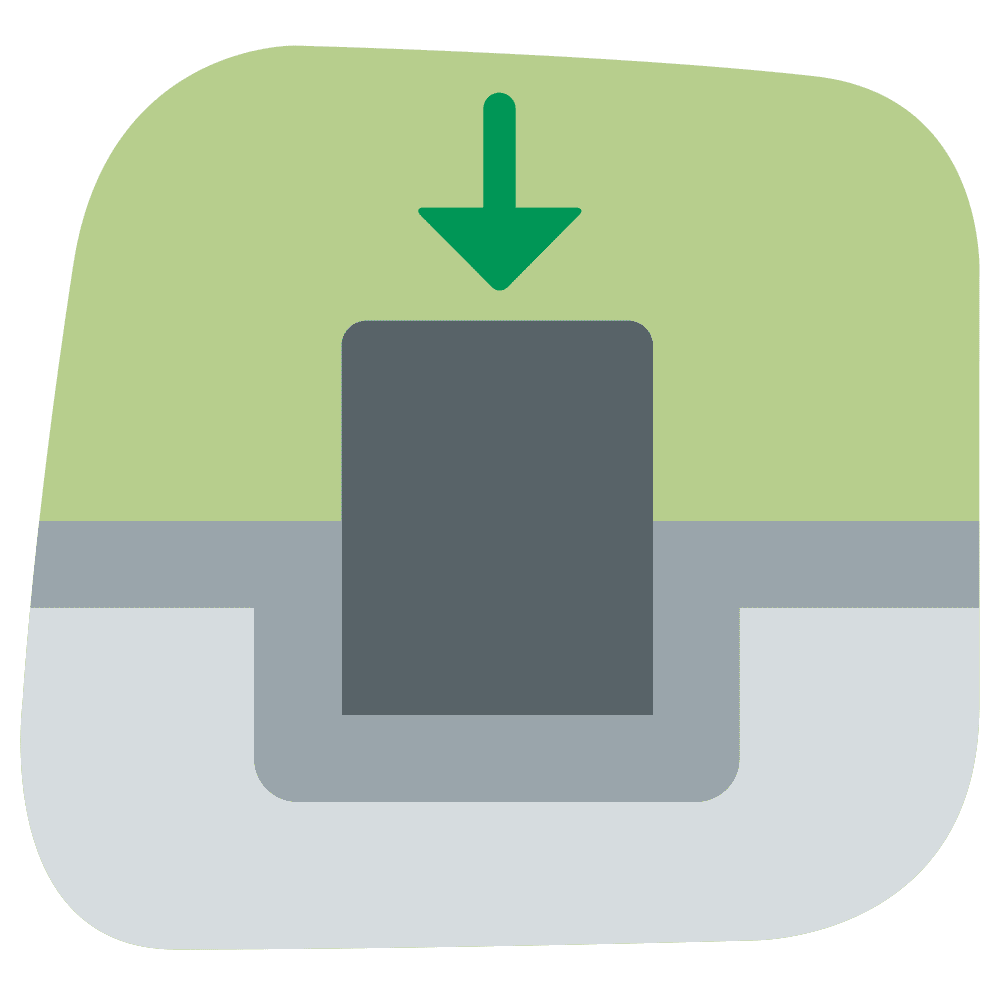

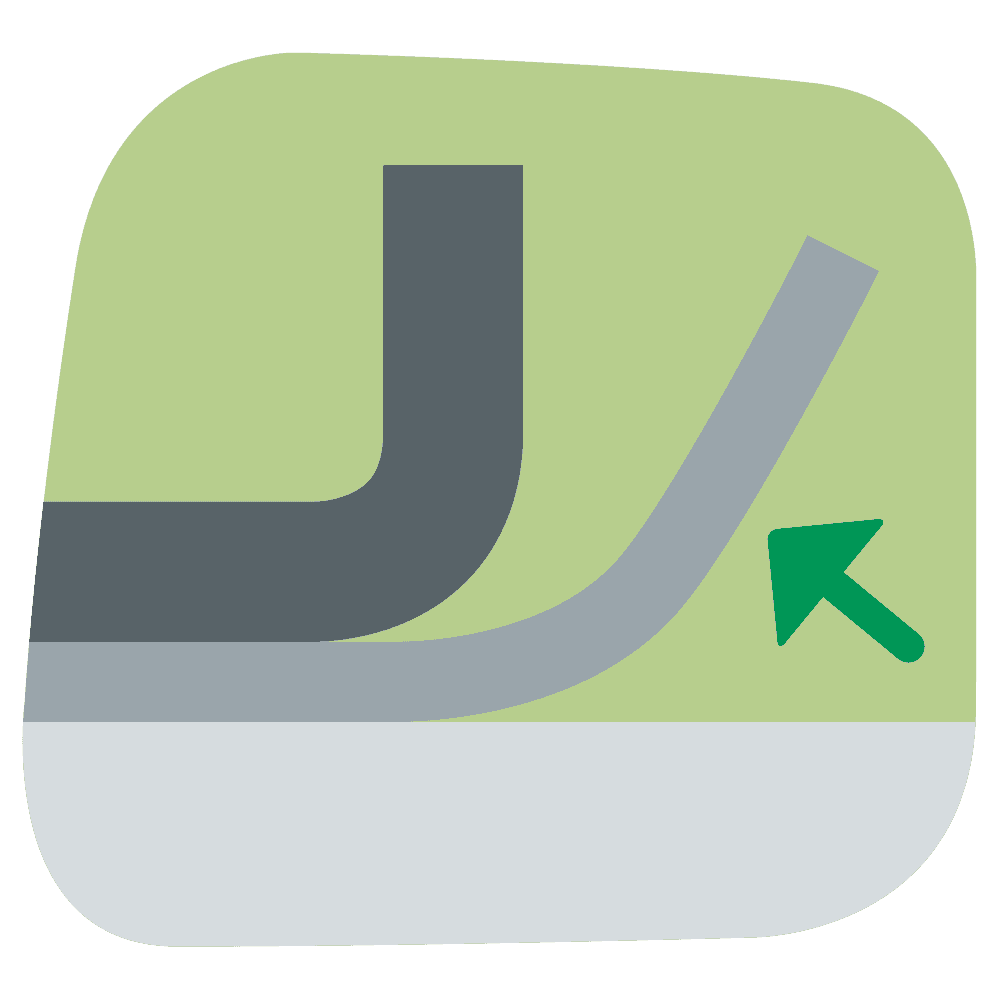

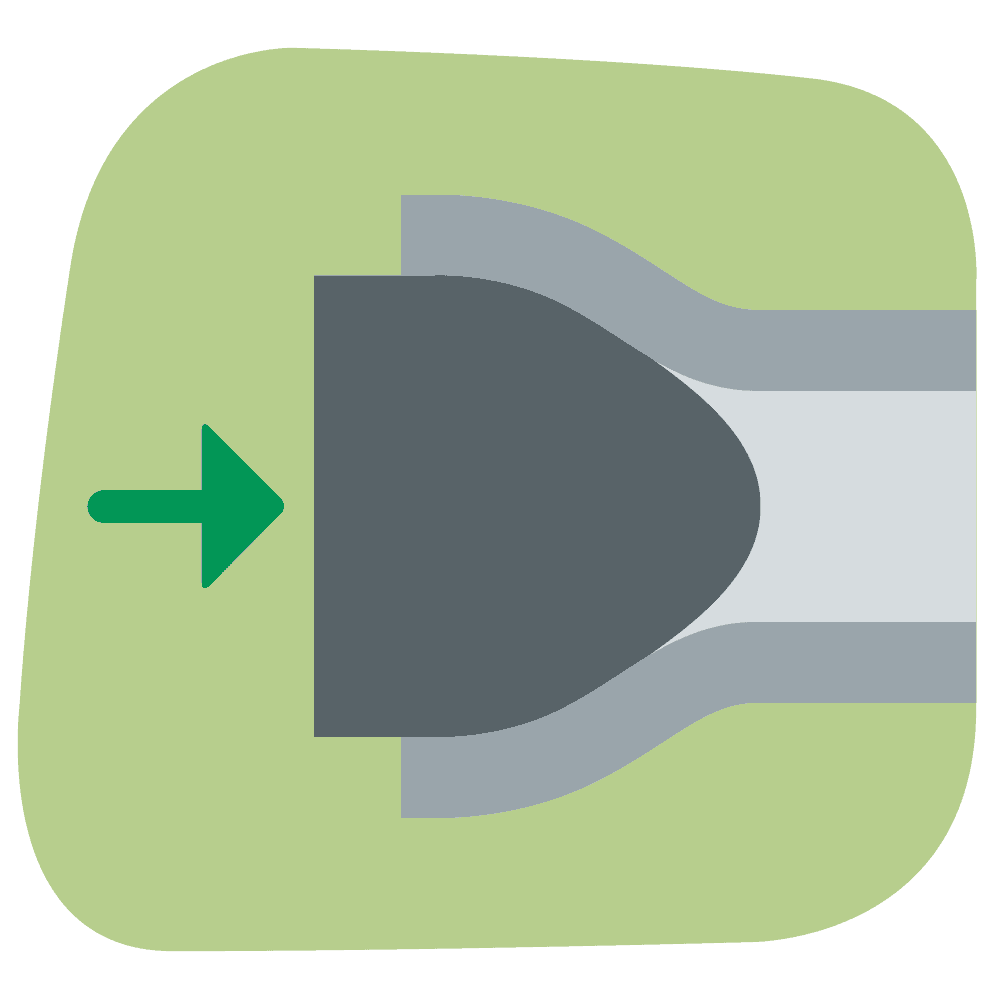

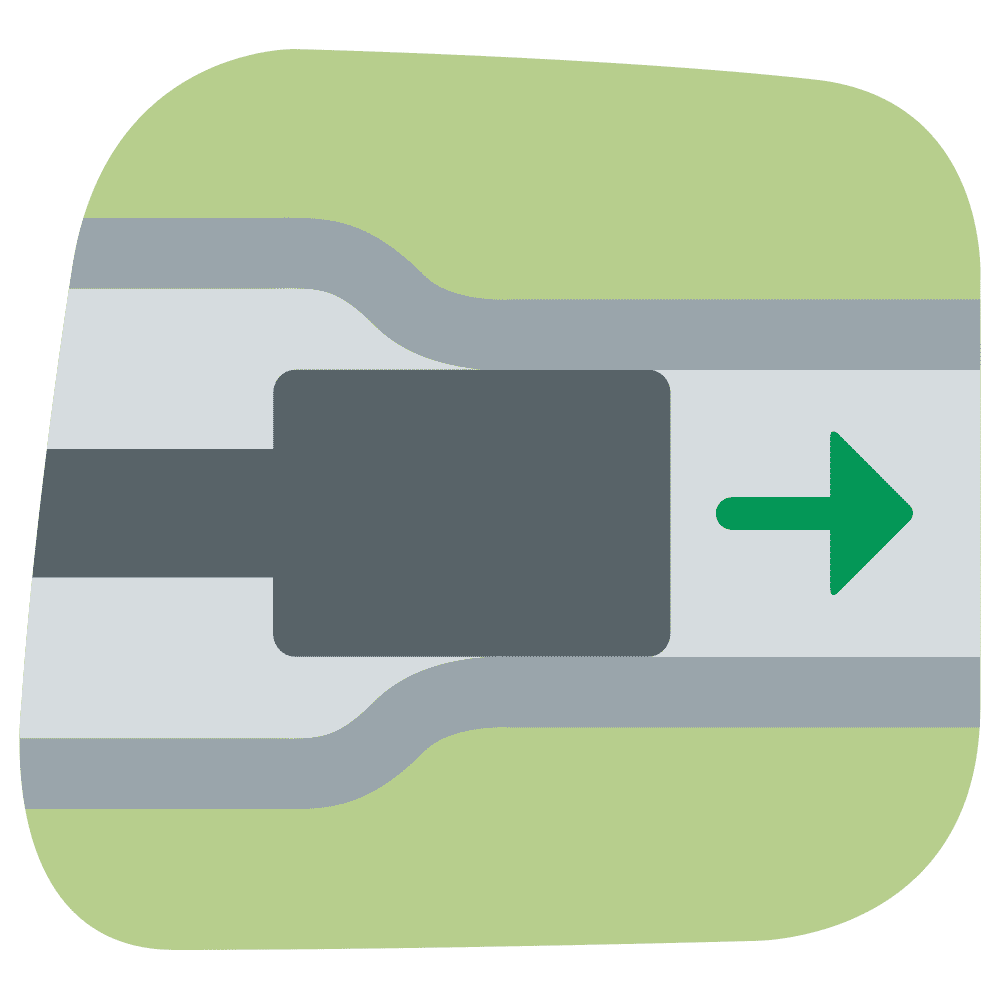

Forming

Deep drawing, bending, expanding or cold extrusion: forming processes often involve high forces that quickly lead to failure in uncoated tools. A GPA coating – possibly in conjunction with prior surface polishing – improves tool life and the quality of the removed parts.

Reduce wear and improve service life

The high hardness of the GPA coatings effectively protects the punch and die against wear. The tool life is extended.

Reduce cold welding

The low coefficient of friction of the GPA coatings, combined with the selection of the appropriate coating variant, reduces the tendency to cold welding in the tool.

Prevent scoring

The hard coating protects the tool surface and prevents the formation of grooves in the tool.

Improve flow behavior

Thanks to the low coefficient of friction of the coating, the material flows better over the shaping contours and can be formed with less force.

Umformen Biegen Weiten Durchziehen Prägen

Improve quality

Fewer cold welds and grooves in the tool lead to an optimization of the removed parts.

Reduce lubricant

Thanks to the low coefficient of friction of the GPA-PVD coating, the use of lubricants can be reduced in many cases without affecting the quality of the finished part or tool wear.

Improve demolding

The low coefficient of friction and the lack of chemical affinity to the workpiece improve the ejection of the finished part. Tool breakage due to jamming is prevented.

Reduce unit costs

The longer tool life in conjunction with higher stroke rates leads to a higher output quantity per tool, which reduces unit costs.

Forming specifications

Material | Application | Usable PDV coatings | Recommendation | Optimisation |

Unalloyed steel und < 500 N/mm2 | Sheet metal | TiCN, CrN, S-Protect, B-Protect | S-Protect | Polishing + TopCoat |

Solid | TiCN, S-Protect | Polishing + S-Protect | ||

Warm | B-Protect, AlCro-Protect | AlCro-Protect | ||

Steel > 500 N/mm2 | Sheet metal, warm | S-Protect, B-Protect, AlCro-Protect | Polishing, AlCro-Protect | TopCoat |

Stainless steel | Sheet metal, solid | S-Protect, B-Protect, AlCro-Protect | Polishing, S-Protect + TopCoat | |

Galvanised sheet steel | Sheet metal, warm | S-Protect, B-Protect, AlCro-Protect | Polishing, S-Protect | TopCoat |

Aluminium alloys | Sheet metal, solid | CrN, B-Protect, DLC-Protect | Polishing, CrN + TopCoat | |

Warm | B-Protect, AlCro-Protect | Polishing, AlCro-Protect | TopCoat | |

Titanium alloys | Sheet metal, solid | B-Protect, AlCro-Protect | B-Protect + TopCoat

| Polishing |

Warm | B-Protect, AlCro-Protect | CrN + TopCoat | Polishing | |

Copper, brass, bronze | Sheet metal, solid, warm | CrN, Sprotect, AlCro-Protect | CrN + TopCoat | Polishing |

Individual coating services: Let us advise you!

Do you already know what you need? Or do you need more information? We have been developing PVD coatings for our customers for over 30 years and are sure to have the right coating solution for your individual application. We also guarantee a fast delivery time! Put your trust in our experience!