Systems

Arc evaporator

GPA started out as a plant manufacturer at the beginning of the 1990s. Our expertise in PVD coatings therefore stems from machine technology. The reliable arc evaporator technology developed by company founder Jürgen Lohmann has been used successfully worldwide ever since.

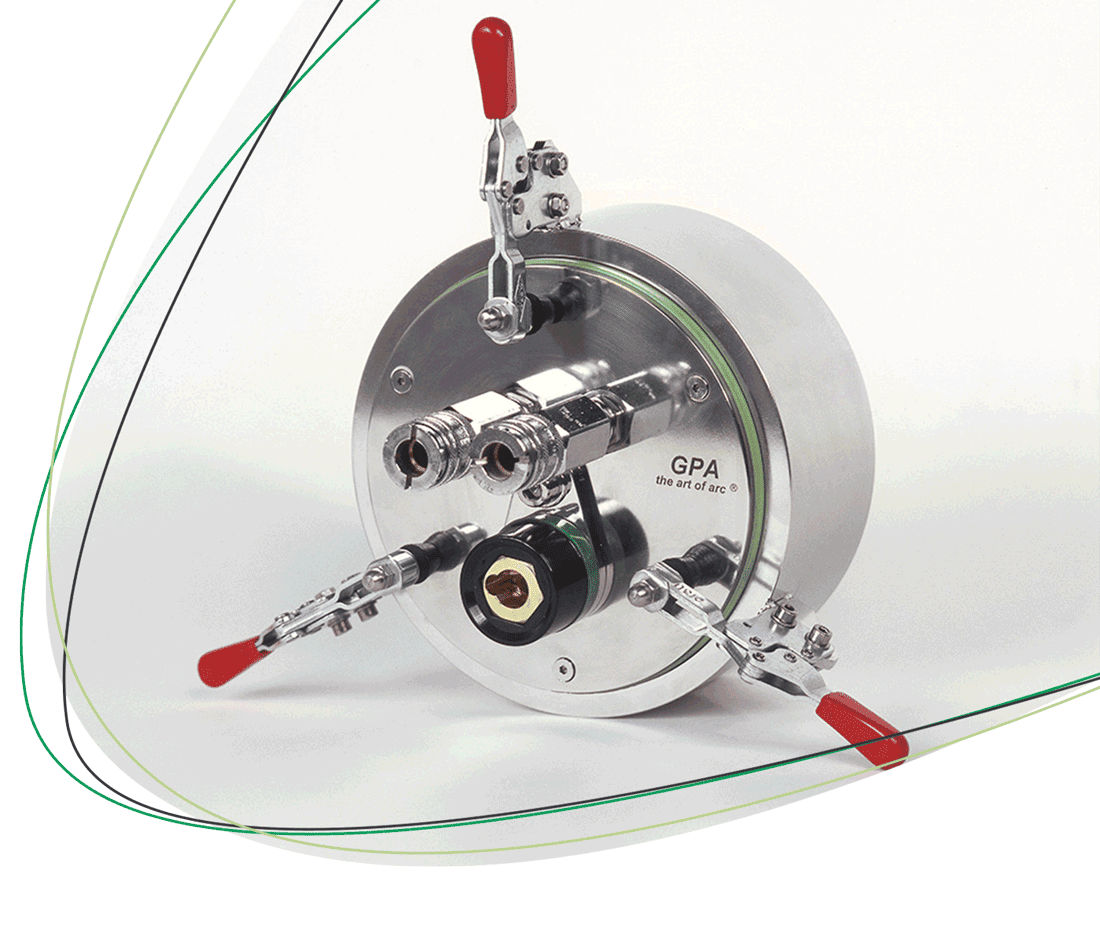

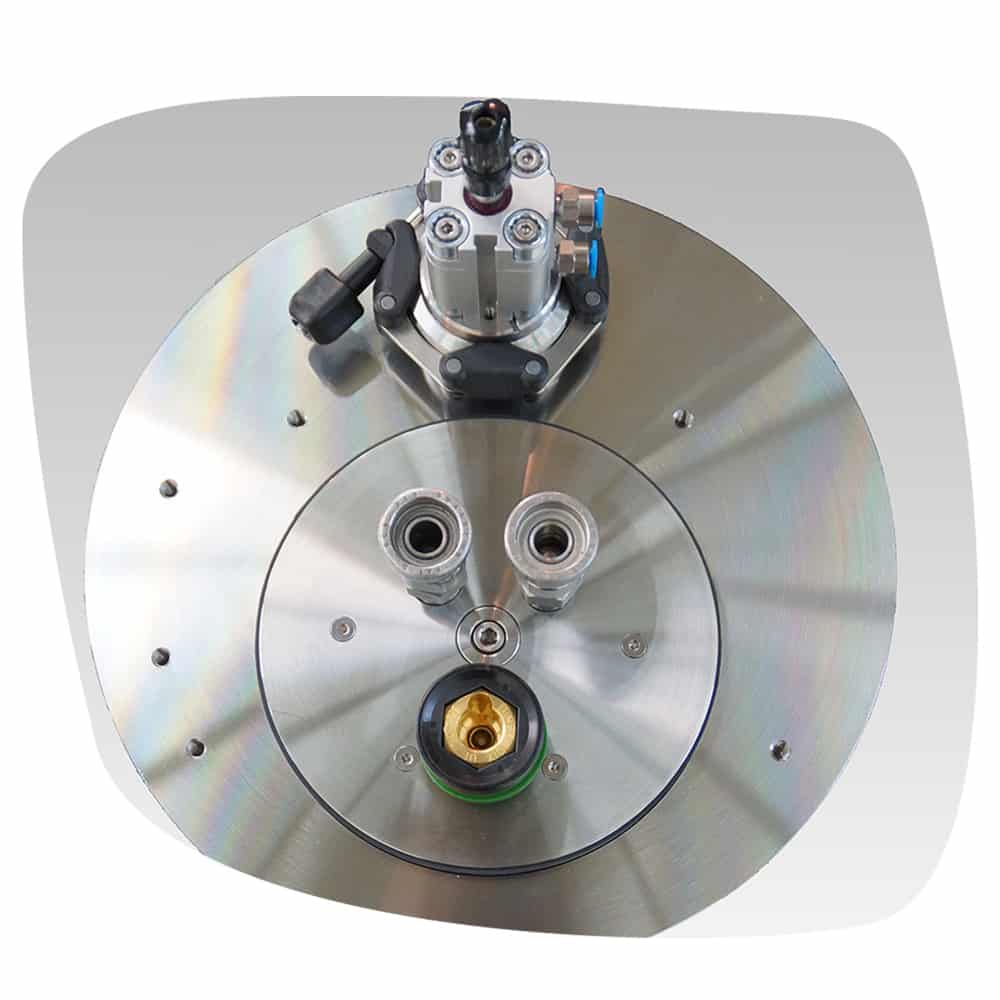

PVD arc evaporator unit (cathodic arc source)

Features

Specifications Arc evaporator

Vaporiser type | Arc Spot-vaporiser |

Arc type | cathodic random arc |

Einsatzbereich

| Industrial production; F&E |

Field of application | any |

Mounting the base module in the flange | Horizontal clamp for fast removal |

Cathode mounting | Quick-change system with clamping ring |

Active cathode diameter | Ø 80 mm |

Active cathode area | ̴ 50 cm2 |

Cathode materials | all known cathode materials |

Cathode utilisation | > 70 % (Reduction in consumption costs) |

Degree of ionisation | up to 90% |

Pressure area | < 7 x 10-2 mbar |

Vaporiser flow | max. 100 A |

Material | Completely 1.4301 or 1.4571 Cathode contact surface made of high-strength copper alloy |

Cooling | Indirect water cooling Cathode surface |

Cooling water connection | Quick-release couplings sealing on both sides |

Cooling water requirement | 10 L / min., 5 bar absolut, 15 – 20 °C |

Trigger unit | Sealed bellows |

Trigger ignition | Electropneumatic |

Arc focussing | Magnetic field |

Dimension | Weld-in flange Ø 165 mm (evaporator) plus weld-in flange KF40 (trigger) |

Construction options | – Weld-in flange Ø 165 plus weld-in flange KF40 (also in existing recipients) - Complete on flange CF or ISO-K from Ø 250 mm - Complete on MA evaporator flange - Complete on customised flange from Ø 250 mm |

Individual coating services: Let us advise you!

Do you already know what you need? Or do you need more information? We have been developing PVD coatings for our customers for over 30 years and are sure to have the right coating solution for your individual application. We also guarantee a fast delivery time! Put your trust in our experience!