PVD coatings

Chromium nitride (CrN)

Best wear protection with pronounced non-stick properties against adhesive molding compounds: Chromium nitride is suitable for processing highly adhesive plastics as well as for forming metals.

CrN for use in various industrial sectors

Chromium nitride coatings are characterized by high ductility and excellent chemical and oxidation resistance. They offer an optimum combination of wear and corrosion protection. They can be deposited comparatively thicker than other PVD coatings while maintaining high hardness.

The low coefficient of friction reduces cold welding, even with minimum quantity lubrication. In combination with a sliding coating (TopCoat) and thanks to the high ductility, the material build-up can also be further reduced when machining soft materials such as copper, brass or aluminum.

This is appreciated in the electrical industry, for example, where adapters for electric charging stations are produced.

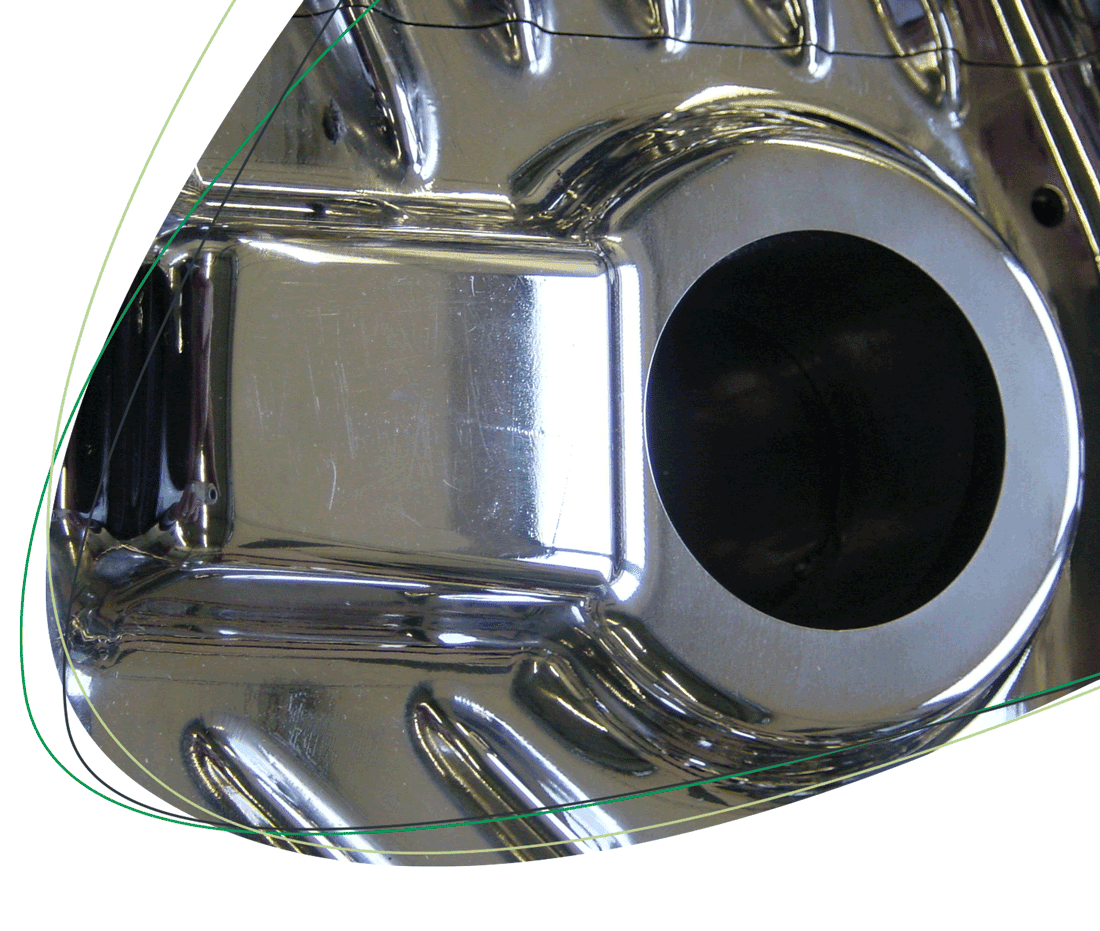

In plastics processing, a coating with chromium nitride improves the flow properties in the tool and prevents the adhesion of plastic residues.

For example, in the production of warning triangles: The dark reverse side is better demolded while the structure remains the same. The safety-relevant front side is transparent, which is why the injection mold is highly polished – changes to it could impair the reflection. The chromium nitride coating protects them against scratches and damage.

The chromium nitride coating can be selectively decoated quickly and easily.

Specifications Chromium nitride (CrN)

Colour | metallic silver |

Hardness | 2.000 – 2.200 HV |

Coating thickness | 3 bis 10 µm jdepending on use and wear type |

Coating temperature | 200 – 500 °C |

Coefficient of friction against steel | 0,57 |

Thermal oxidation resistance

| 700 – 750 °C |

Decoatability | of all steel qualities and carbide |

Areas of application | Wear and corrosion protection, forming, plastics processing, aluminium stamping, deep drawing |

Individual coating services: Let us advise you!

Do you already know what you need? Or do you need more information? We have been developing PVD coatings for our customers for over 30 years and are sure to have the right coating solution for your individual application. We also guarantee a fast delivery time! Put your trust in our experience!