PVD coatings

AlCro-Protect® (AlCrN)

Extreme conditions require extreme resistance: where the coating process gets hot, the mixture of aluminum and chrome is the right choice. AlCro-Protect® defies any heat of battle.

AlCrN: rightly in great demand

The Heat is on. The basic theoretical idea behind the development of this coating was that a combination of aluminum and chrome can absorb very high temperatures. The practical result: our AlCro-Protect® can withstand temperatures of up to 1,200 °C.

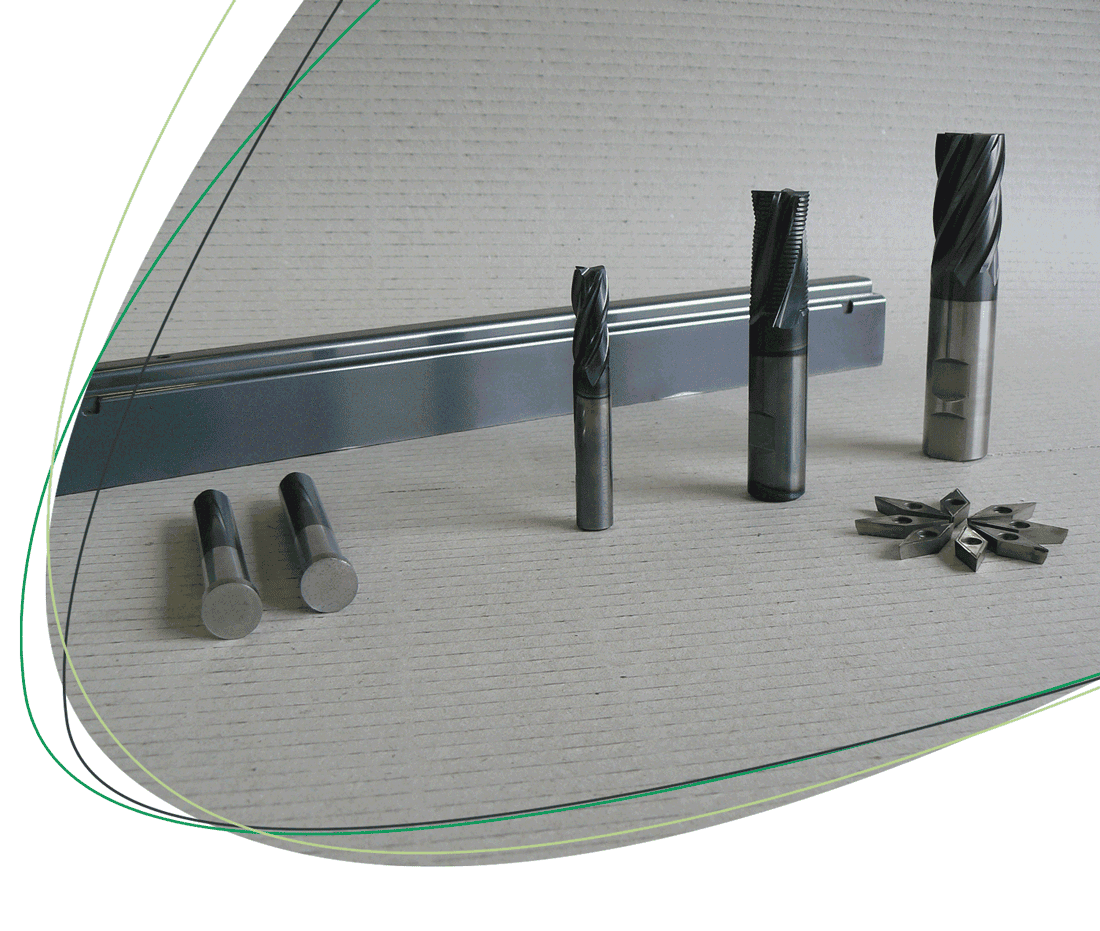

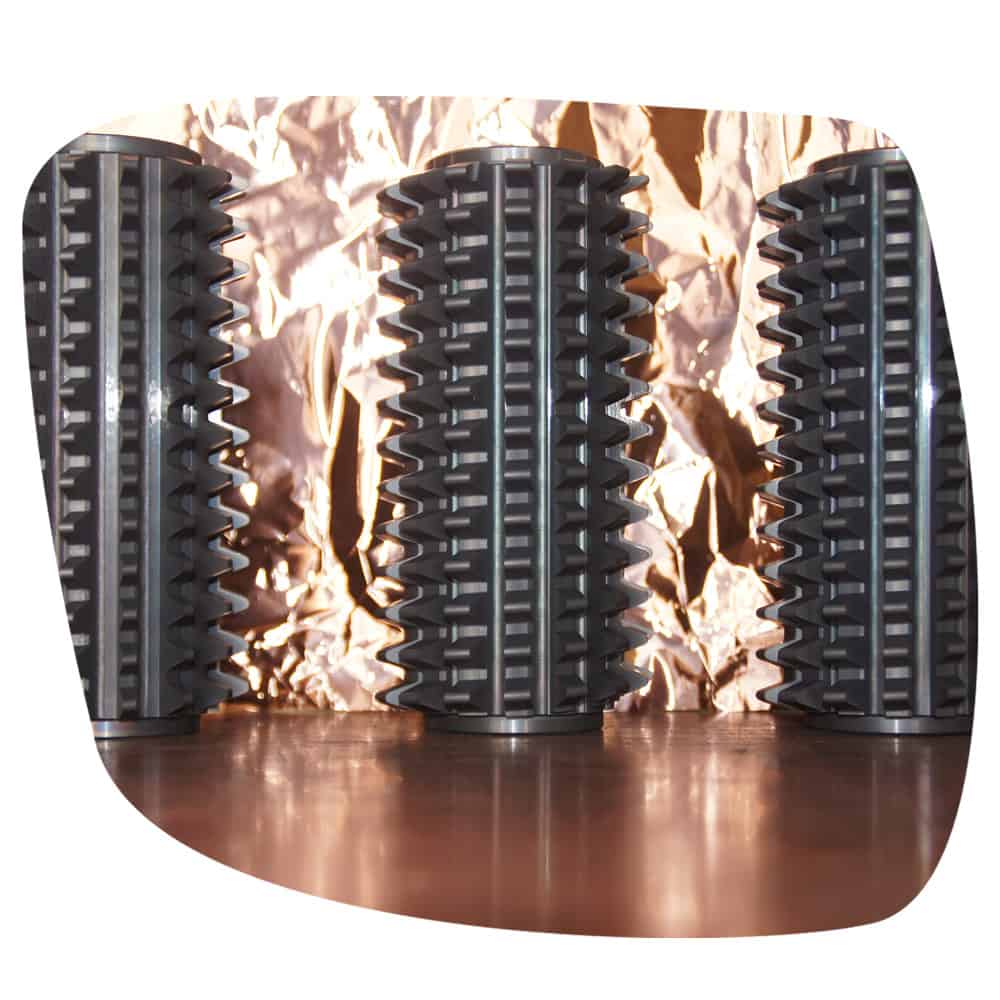

Where high cutting speeds have to be achieved with drills and milling cutters during machining – for example in gear production – high levels of friction and heat are generated. This is where the advantages of AlCro-Protect® really come into their own. Thanks to the AlCro-Protect® coating, module milling cutters are also less prone to cold welding and abrasive wear is reduced.

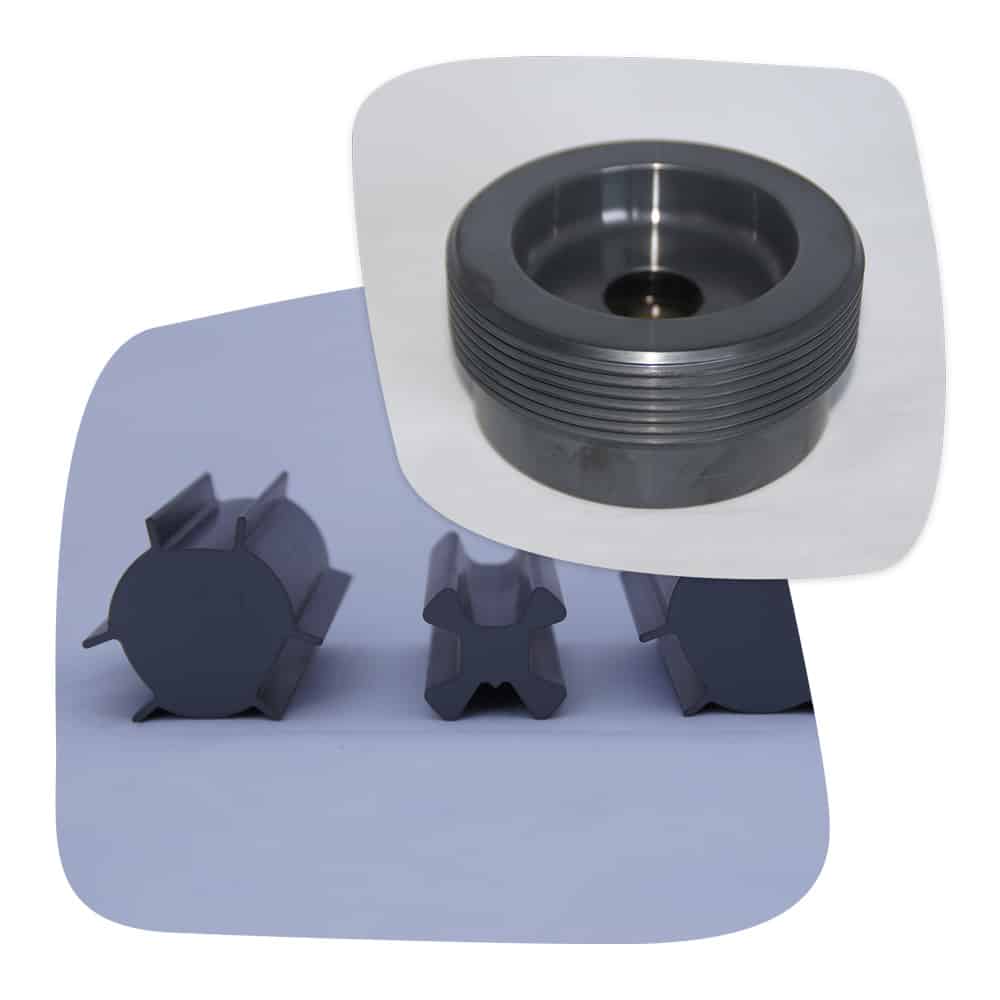

The high hardness and slight ductility not only prove themselves in machining operations, but also enable better tool life and a very fine surface quality in punching, bending, cutting and forming. This also pleases end customers such as Mercedes Benz – although in most cases we don’t even know them because we rarely know what is actually produced with the tools we coat. Isn’t that almost a bit of a shame?

The AlCro-Protect® can be selectively decoated quickly and easily.

Specifications AlCro-Protect® (AlCrN)

Colour | blue-grey |

Hardness | 3.100 – 3.200 HV |

Coating thickness | 2 – 5 µm depending on use and wear type |

Coating temperature | 300 – 500 °C |

Coefficient of friction against steel | 0,35 |

Thermal oxidation resistance | 1.100 °C |

Decoatability | of all steel qualities and carbide |

Areas of application | Hobbing, turning, milling, forming, deep drawing, punching, indexable inserts |

Individual coating services: Let us advise you!

Do you already know what you need? Or do you need more information? We have been developing PVD coatings for our customers for over 30 years and are sure to have the right coating solution for your individual application. We also guarantee a fast delivery time! Put your trust in our experience!