PVD coatings

DLC-Protect®

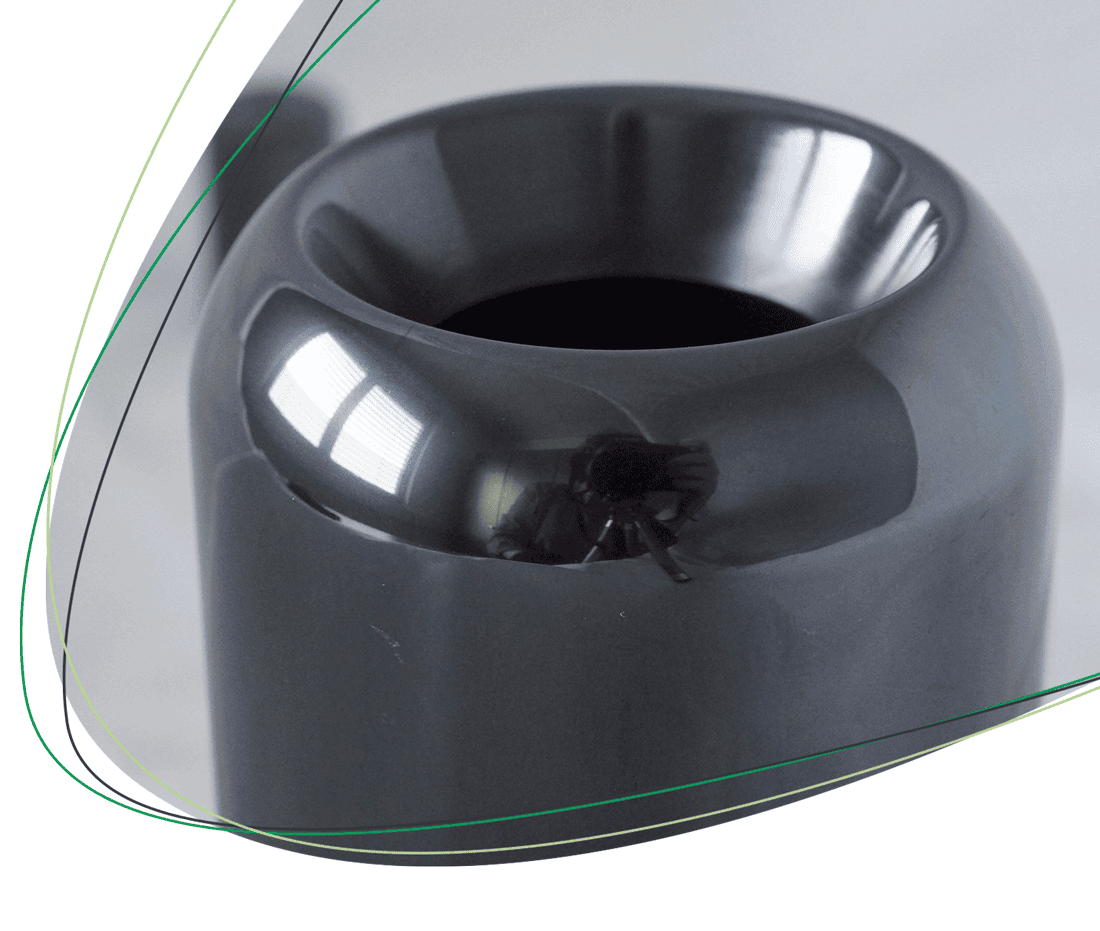

With coatings, “Shine bright like a diamond” means: Shine with your performance characteristics – in the case of DLC with a high surface hardness and an almost unique smoothness (a low coefficient of friction).

DLC coatings: tough as nails

Diamonds are a Mold’s best Friend. High hardness with a low coefficient of friction: DLC-Protect®, our Diamond-Like-Carbon coating, combines the properties of diamond and carbon in one coating system. It reduces the tendency to cold welding and at the same time offers protection against corrosion and abrasive wear.

Due to the low coating temperature, non-ferrous metals can also be coated without any problems. The DLC-Protect® coating can also be used for the internal coating of drill holes and openings.

Specifications DLC-Protect®

Colour | anthracite to black |

Hardness | 1.500 – 2.000 HV |

Coating temperature | 170 °C |

Coefficient of friction against steel | 0,15 |

Thermal oxidation resistance | up to 360 °C |

Decoatability | Yes |

Areas of application | Component coatings: Bolts, pistons, valves; plastics processing: ejectors, slides; dry running of drive elements (spur gears, shafts, plain bearings, emergency running of bearings); machining: non-ferrous metals, avoidance of built-up edges when machining aluminium; forming: of aluminium |

Individual coating services: Let us advise you!

Do you already know what you need? Or do you need more information? We have been developing PVD coatings for our customers for over 30 years and are sure to have the right coating solution for your individual application. We also guarantee a fast delivery time! Put your trust in our experience!