PVD coatings

S-Protect®/ S-Protect-Plus®

Our goal is ambitious: With our PVD coatings, we want to create tools that cannot be destroyed by anything. Anyone who says “dream on …” should take a look at our S-Protect®.

Borders are there to be crossed

Do you know our corporate vision? We want to make tools indestructible! The S-Protect® comes closest to this vision: it makes your tool virtually indestructible. That speaks against our business, but very much in favor of our customer friendliness, don’t you think?

The following applies to stainless steel: S-Protect® combines the positive properties of the CrN coating with significantly increased hardness and an improved coefficient of friction. In combination with a surface polish and anti-friction coating (TopCoat), abrasive wear and the tendency to cold welding can be reduced when machining stainless steel.

With its extremely low coefficient of friction, first-class adhesion to the substrate and good polishability after coating, S-Protect® is also suitable for applications where the CVD process is difficult or impossible to use due to high process temperatures.

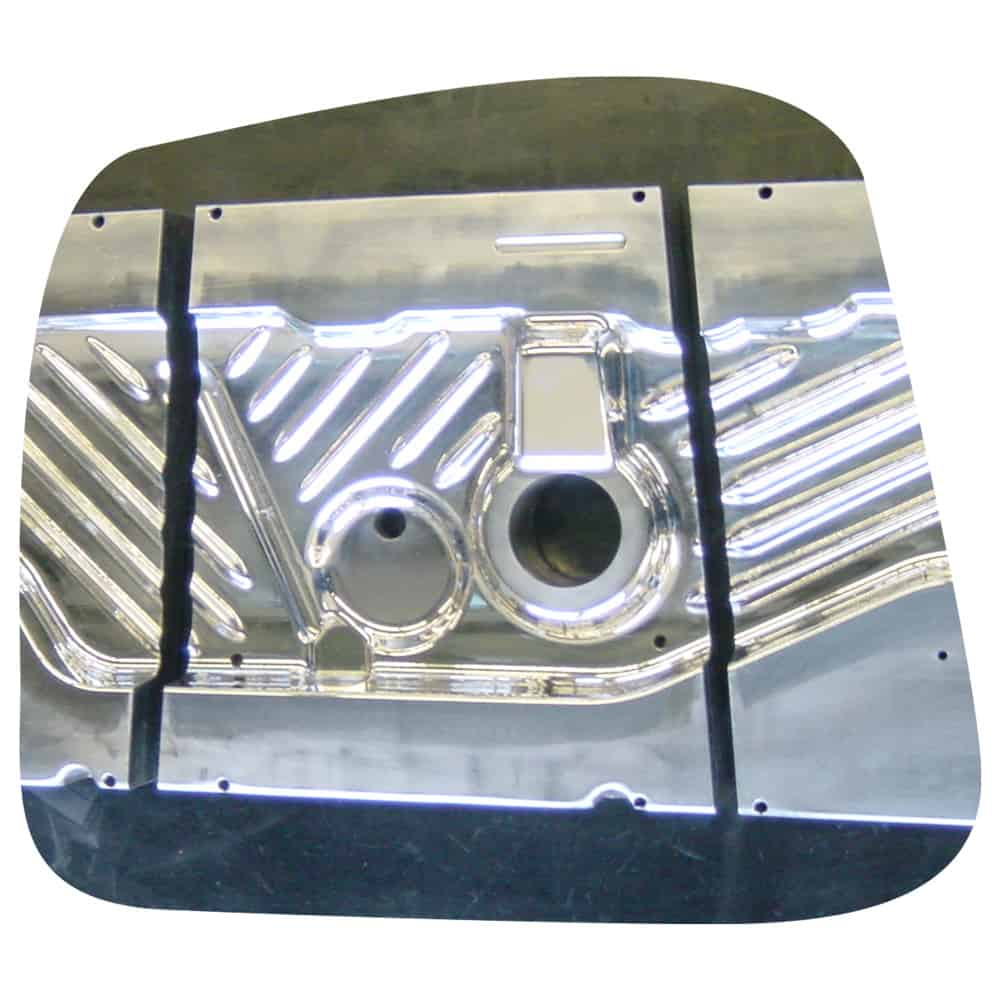

When processing a soft medium such as aluminum, the S-Protect® protects against adhesive build-up of material. This is probably the reason why many profile manufacturers are among our customers and have us coat their profile and form rolls. We have users whose tools have been running for years thanks to a little trick and the S-Protect® coating.

Our coating expert Uwe Haas will be happy to explain the exact background (including a possible trick!) in a personal meeting.

S-Protect® and S-Protect-Plus® are used in forming processes – bending, drawing, embossing – and can be selectively decoated quickly and easily.

Specifications S-Protect® / S-Protect-Plus®

Colour | silver-grey |

Hardness | 2.700 HV |

Coating thickness | bis 10 µm depending on use and wear type |

Coating temperature | 200 – 500 °C |

Coefficient of friction against steel | 0,32 |

Thermal oxidation resistance | 500 – 600 °C |

Decoatability | of all steel qualities and carbide |

Areas of application | Forming, solid forming, embossing, drawing, wear and corrosion protection of components |

Individual coating services: Let us advise you!

Do you already know what you need? Or do you need more information? We have been developing PVD coatings for our customers for over 30 years and are sure to have the right coating solution for your individual application. We also guarantee a fast delivery time! Put your trust in our experience!