Sliding and demolding coating

TopCoat

Everything has to fit together in the PVD coating process. Our TopCoat works as a stand-alone coating in the plastic injection molding industry or as the perfect complement to our PVD hard coatings in metalworking.

Perfection on top

How does the pacifier come out of the mold more easily? With our TopCoat anti-friction coating: a tungsten-based coating that can be applied directly to the base material or to a PVD hard coating. Like an oil film, it prevents direct contact between the friction partners. The result: the tendency to cold welding is reduced and the emergency running properties of highly stressed components are improved.

TopCoat originally comes from the plastics industry and can also be used as a stand-alone coating for plastics. Meanwhile, the coating also works extremely well in combination with our hard coatings as a demolding aid. We use them very successfully as a supplementary layer for customers who do not use temperature-resistant steels.

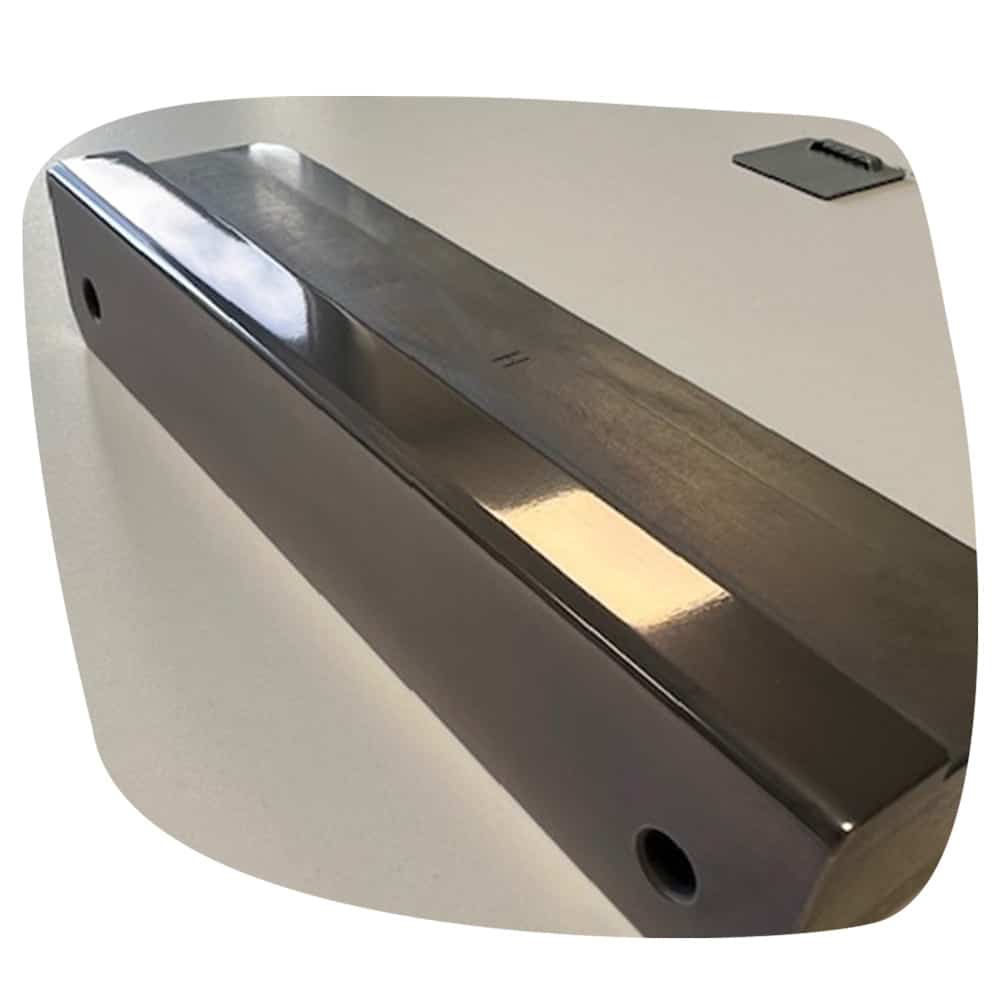

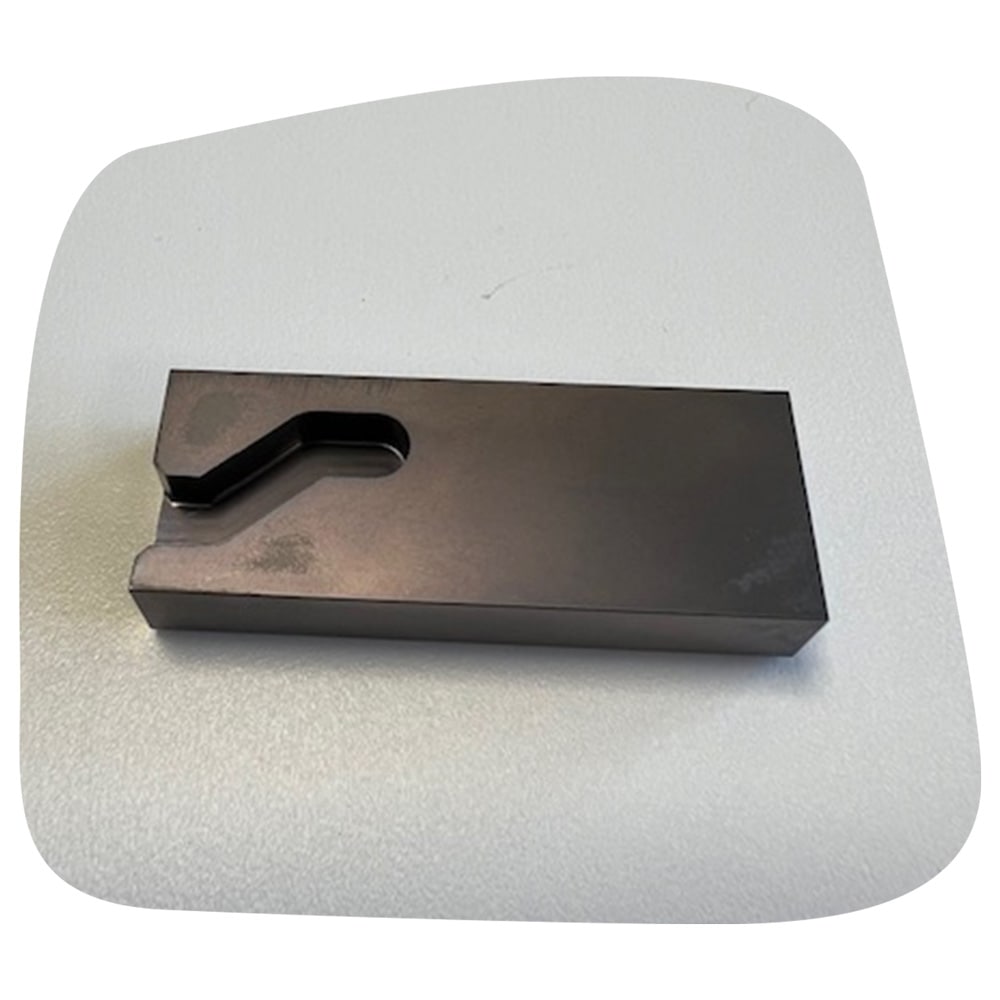

A successful example from stainless steel processing: The customer was desperate. During punching, the punch heads or functional surfaces of the punches used tore off, even though they were already equipped with a TiCN coating. The additional application of the TopCoat further reduced friction and significantly improved the plunging and return of the punch.

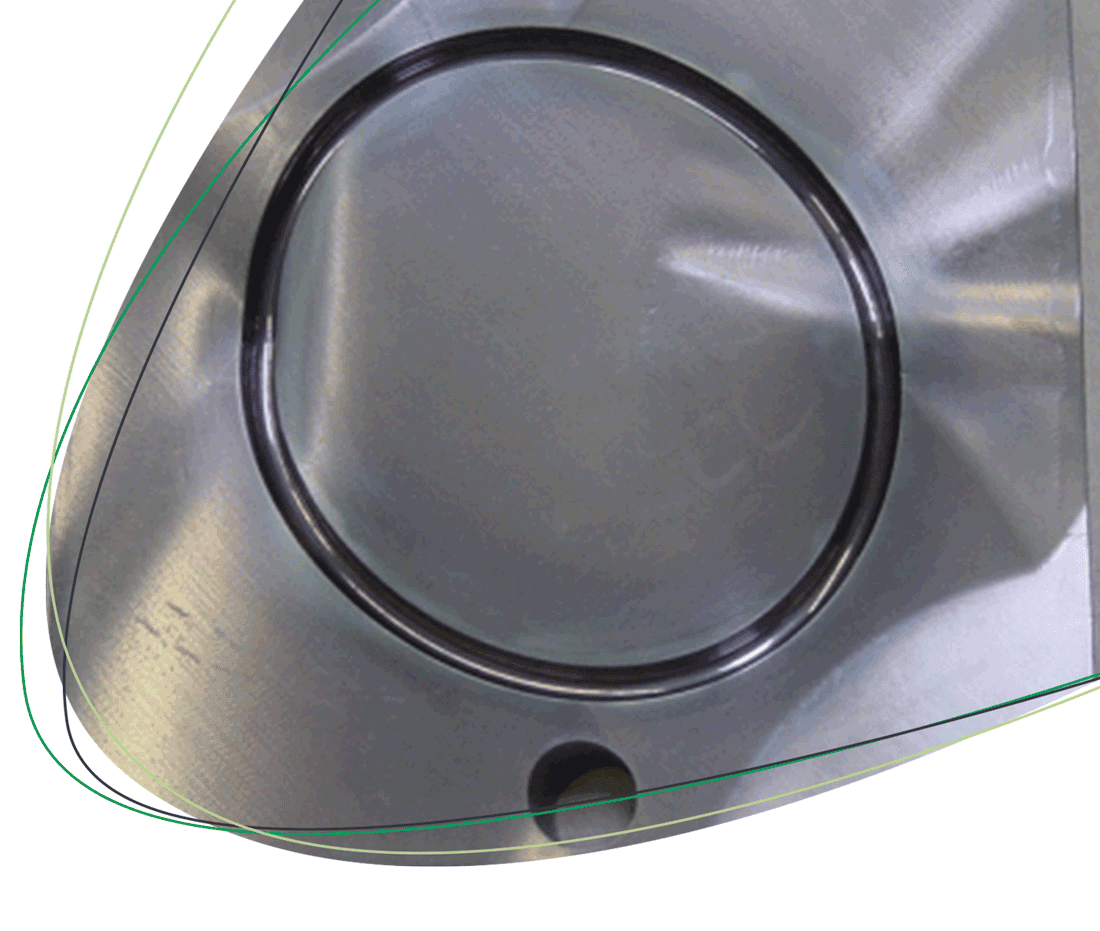

A successful example from plastics processing: the anatomical shape of baby pacifiers can be a challenge in the production process. What should I do if the silicone or natural rubber (latex) pacifiers get stuck in the mold during the injection process? We have equipped both halves of the tool with TopCoat, which has considerably reduced the plastic’s tendency to stick.

Specifications TopCoat

Colour | bluish grey |

Hardness | 1.500 – 2.000 HV |

Coating thickness | 0,5 µm

|

Operating temperature | -150 bis 500 °C |

Areas of application | Drilling, turning, milling, broaching, cutting, sawing, cold extrusion, forming, bending, plastics processing |

Individual coating services: Let us advise you!

Do you already know what you need? Or do you need more information? We have been developing PVD coatings for our customers for over 30 years and are sure to have the right coating solution for your individual application. We also guarantee a fast delivery time! Put your trust in our experience!