Systems

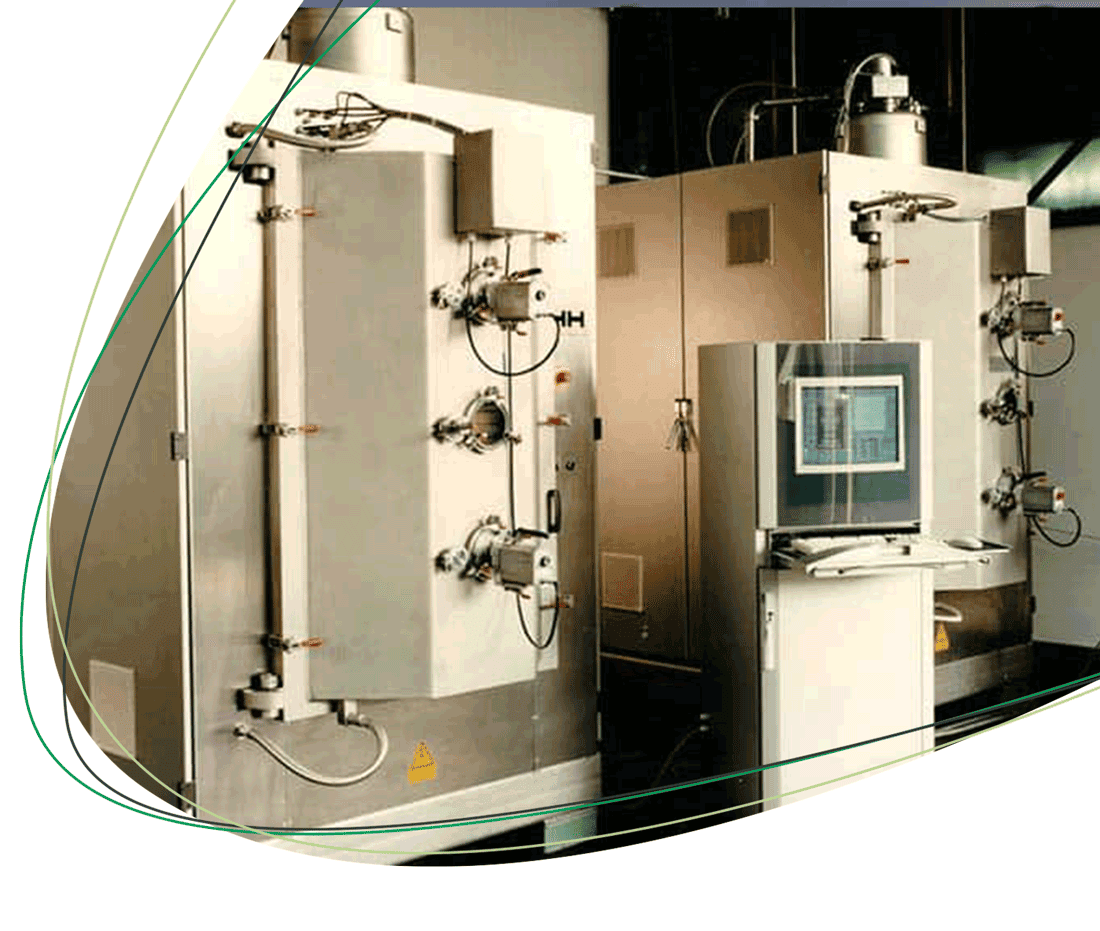

PVD system 10-950

The PVD system 10-950 is a large system designed for special tools, e.g. broaching tools. A chamber height of 1.50 m and a volume of 950 liters characterize the largest system in our series to date.

PVD system 10-950

Like all GPA-PVD systems, it is built according to a concept that guarantees robustness and a long service life.

Specifications PVD system 10-950

Coating chamber | Dimensions Ø 900 x 1.500 mm Material austenitic steel double-walled; fully cooled or bakeable |

Rotary drive | Infinitely variable speed control Clockwise/anticlockwise rotation Batch weight up to 500 kg |

Vaporiser | 10 arc-spot evaporators in 2 rows of 5 active cathodes 50 cm2 each; Alternatively 12 arc-spot evaporators in 3 rows of 4 active cathodes 50 cm2 each |

Vaporiser power supplies | 10 pieces (alt. 15 pieces) max. 100 A |

High-voltage supply | 0 - 1.000 V unipolar pulsed 0 - 50 ADC 0 - 120 APulse fast arc switch-off |

Substrate heating | 4 heaters 15 kW each |

Substrate temperature measurement | Pyrometer 150 – 550 °C |

Process gas control | 4 mass flow controllers (Ar, H2, N2, carbon carrier gas) |

Backing pumping unit | Rotary vane/rotary pump combination Suction capacity S 730 m3 / h |

High vacuum pump | Cryopump suction capacity H2O 18.000 ; Ar 3.700 ; N2 5.000; H2 5.500 L/sec. |

High vacuum valve | Stepper motor-controlled control valve DN 400 |

Vacuum measurement | Pirani gas type independent measuring device |

Process control | Fully automatic, industry PC parameters, ramps etc. freely programmable |

Accessories (optional) | Cold/hot water supply

Process gas supply Triple planetary rotating substrate holder |

Individual coating services: Let us advise you!

Do you already know what you need? Or do you need more information? We have been developing PVD coatings for our customers for over 30 years and are sure to have the right coating solution for your individual application. We also guarantee a fast delivery time! Put your trust in our experience!