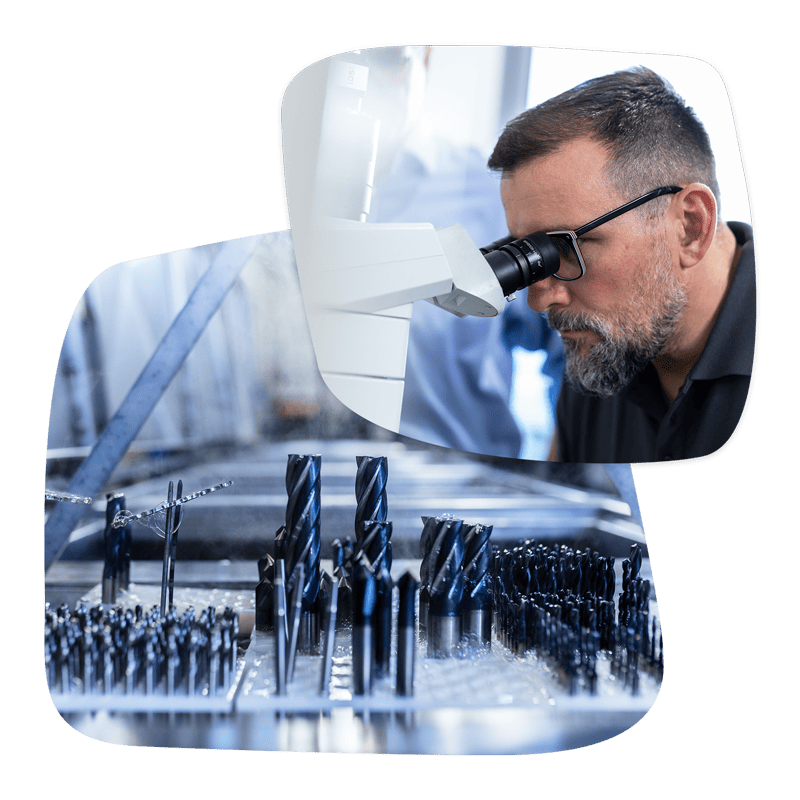

Premium PVD coatings from GPA

High-tech in harmony with the environment

Get a head start and get the most out of your tools and components. GPA coating technology makes your components even more wear-resistant, durable and efficient. This is ecologically sensible and economically beneficial: because what lasts longer is significantly more sustainable and minimizes the downtime of your production.

GPA Coating also pays off for you

As a toolmaker, production or plant manager, you know the impact of coating your tools: it not only reduces tool costs, but also tool life, lubricants and headaches.

If you are a managing director, controller or purchaser, we will be happy to provide you with facts and figures: You will no longer have to invest so heavily in your tools once we have coated them.. Simply because they last longer and reduce process fluctuations.

Our satisfied customers come from a wide range of industries. Where are you at home?

Your industry is not listed?

No problem, we are sure to find the right solution for your applications.

Coating services from GPA: Tough times for your tools

We would love to make your tools indestructible. And to be honest: We are working on it. Our ultra-thin PVD coatings protect tool steels, powder metallurgical steels and carbides from wear – and your company from unnecessary maintenance costs and losses due to production downtime.

TiN, TiCN, AlTiN, AlCro, CrN or S-Protect: Each of our coatings impresses with unique properties and excellent adhesive strength!

What use is the best coating if it doesn’t suit the application?

PVD coatings from GPA are as individual as your components and precision tools. We know that you need customized solutions for your success and we also understand your individual requirements. We provide you with the best advice first and then the best quality for you.

Allow me, GPA: High-tech coating made in Germany

We come from the plant engineering sector and our core competence is arc evaporator technology – developed in-house and perfected over three decades. Today we can use plasma, this fascinating 4th state of matter, to make your tools virtually indestructible. By the way, did you know that stars, and therefore 99% of all matter in the universe, consist of plasma?

“There is something very special about seeing a plasma. Our machines can extract an electron from atoms and shoot them at a tool. What happens in detail is fascinating: a metal flies off and a ceramic lands on the workpiece.”

— Richard Kallee, managing director and physics nerd

Fast, faster, GPA Coating

The fact that our PVD coatings improve the performance of your tools and components is sustainable, resource-saving and economical. Those who work with us also appreciate our reliability, flexibility and adherence to deadlines! Over the last three decades, we have optimized and simplified our coating processes to such an extent that we can now deliver very quickly: top quality within 2 to 3 days.

“We are proud that we can organize the regular coating and recoating of tools and components in such a stable and reliable way. This saves our customers valuable time. We are often told: Ordering from you is so pleasant because everything is so precise and fast.”

— Uwe Haas, Technical Sales

Your advantages at a glance

Pick-up and delivery service

Efficient logistics: pick-up and delivery service

We collect the tools from you and deliver them – PVD-coated in first-class quality – directly back to you within 2 to 3 days.

Online calculator: How much does your GPA coating cost?

Use our guide price calculator and get a quick and easy overview of costs: Enter your dimensions and data and calculate the standard price for your coating online. Tip: Larger quantities lead to even better prices!

Questions and answers

Please contact us personally if you require further information.

Get in touch with us

Do you have questions or are you looking for specific information? Discuss your challenges with us. We look forward to hearing from you. We will of course treat your data confidentially.