PVD coatings

Noble is the tool, helpful and good…

… and if possible, also very durable! Because wear-resistant, hard-wearing tools are the key to efficient production. The magic word in this context is PVD coating – a synonym for durability, higher productivity and lower production costs for manufacturing companies and toolmakers.

PVD technology: Trust in our experience

Industry and trade have long relied on physical vapor deposition (PVD for short) when it comes to optimizing the performance and resilience of their tools and components. We have been valued as an ideal partner for customer-specific developments in the field of surface optimization and PVD coating for over 30 years.

Precisely fitting PVD coatings for your application

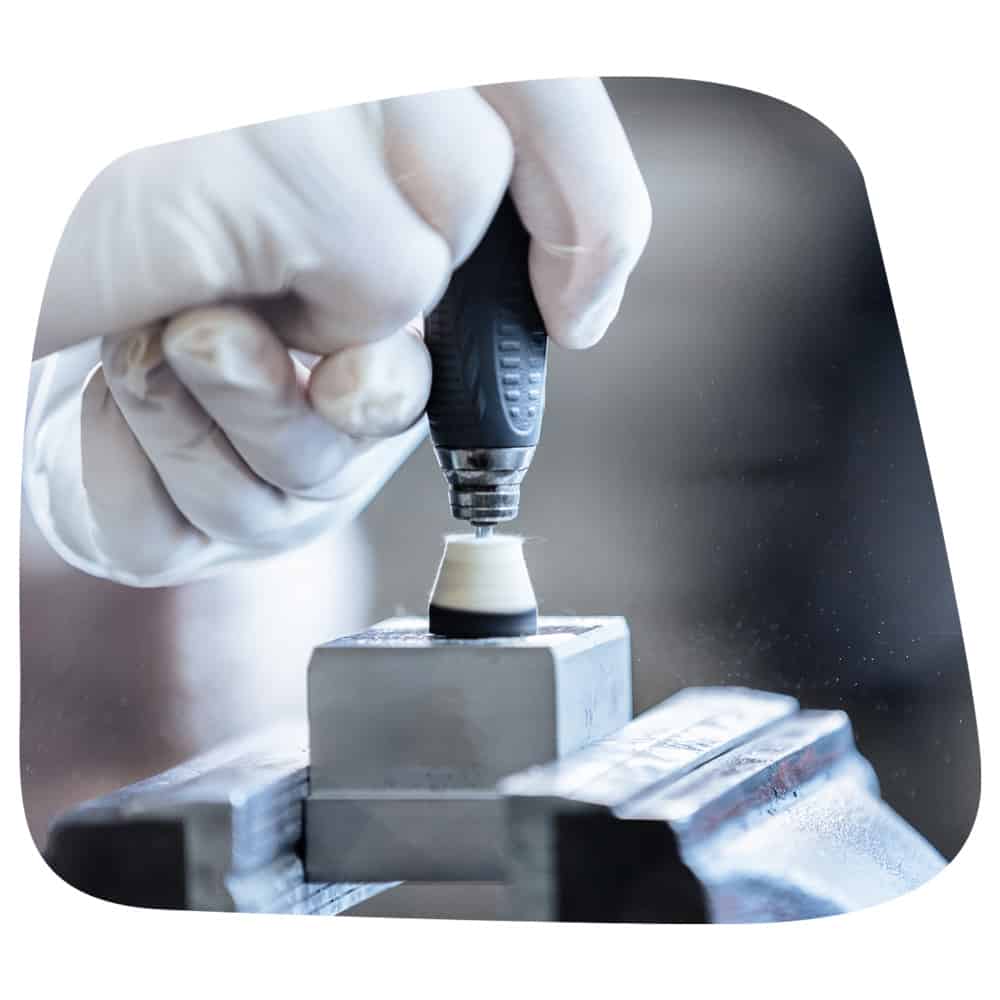

Hard, harder, PVD-coated: Our wear protection processes push the limits of your tools and enable maximum performance when machining demanding materials. With a coating that is only 2 to 10 thousandths of a millimeter thick, we make tool steels, powder metallurgical steels and carbides so much more resilient that the service life of your tools is significantly extended. Will this transform your production? In any case.

Which of our products is best suited to your applications depends on both the intended use and economic considerations. We can say from experience: The optimum coating is always individual and is adapted by us to the requirements of your tool material and the requirements of the respective tool design.

“Why are we able to act in such a binding and reliable manner? Because of our experience! We have developed countless systems ourselves over the last three decades and can therefore rely on mature processes and many best practices.”

— Richard Kallee, Managing Director

Better performance for your tools

PVD-coated tools have long been the game changer in the modern manufacturing industry. In a world where every second counts, they can drastically reduce the downtime caused by tool changes. On the one hand, because they are robust and protected against corrosion and abrasion. On the other hand, through improved demoulding behavior, especially with complex injection moulds and drawing/forming tools: The manufactured parts slide out of the mould much more easily.

Surface finishing – so useful, so fascinating

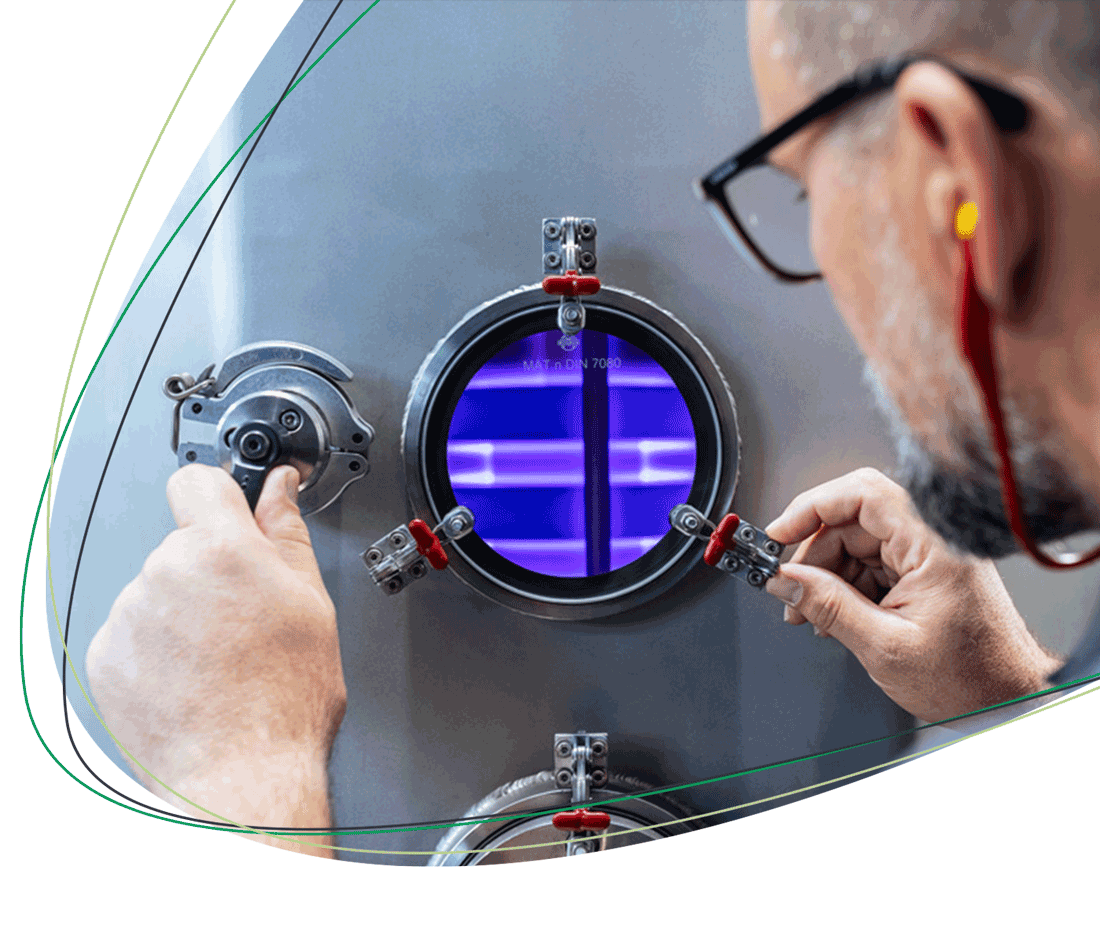

There are various PVD processes in the industry that differ in their methodology: electron beam evaporation, magnetron sputtering and the arc process.

Due to the high adhesive strength of the coatings produced, we rely on the arc process – exclusively and on the basis of our own developments, which are the result of our decades of experience as well as market and customer requirements.

The science behind PVD coating is as useful as it is fascinating. In a vacuum chamber process, metallic materials are vaporized and react with one or more reaction gases to form so-called hard material layers, as they are also known due to their ceramic properties. When applied to the tools, they form an extremely thin but very adhesive protective layer.

How arc evaporation technology works

An arc is used to convert a solid metal target into a gaseous state: An electric arc is ignited between the material to be vaporized, the cathode, and an anode, which is nourished by the vaporized material itself and moves more or less randomly across the cathode surface. Due to the high energy density in the cathode spot – the contact point of the arc on the solid cathode – material is removed there.

Common metals that are used in high-purity solid form as coating materials include titanium and chromium, as well as alloyed cathodes made of titanium-aluminum and chromium-aluminum. As a result, there are also different PVD coatings such as TiN, TiCN, AlTiN, AlCro or CrN: each with unique properties suitable for specific industrial applications and excellent adhesion strength.

Your PVD coating: Holds, fits, has no air

PVD coatings adhere to the surface purely adhesively and do not penetrate the base material! Due to their high hardness, they are also brittle and only adhere due to the low layer thicknesses. They are therefore also known as “thin layers”. Because they are within all tolerances, they do not affect the tool geometry in most cases. As a customer, you can rely on maximum adhesive strength without having to worry about a loss of hardness, distortion or any influence on the microstructure of the steels or carbide – provided the material has been tempered at a minimum of 200 to 250 °C.

More performance layer by layer

Depending on the internal structure of the coating, we speak of monolayer, multilayer or nanolayer coatings.

Surface coatings for all situations

PVD coatings are used for a wide variety of tools and components and are primarily used in stamping, machining, forming technology and plastics processing – in many industries, including sensitive ones such as medical technology and the food industry:

Important for all coatings!

A PVD coating is there to protect a perfect production tool from wear and make it even more durable and not to compensate for faulty tool preparation – even if it could in theory and sometimes in practice. In other words, the efficiency of any coating also depends on the correct preparation and condition of the tool, especially its surface.

Online calculator: How much does your GPA coating cost?

Use our guide price calculator and get a quick and easy overview of costs: Enter your dimensions and data and calculate the standard price for your coating online. Tip: Larger quantities lead to even better prices!

Summary of PVD coatings: The most important facts in brief

Individual coating services: Let us advise you!

Do you already know what you need? Or do you need more information? We have been developing PVD coatings for our customers for over 30 years and are sure to have the right coating solution for your individual application. We also guarantee a fast delivery time! Put your trust in our experience!