PVD coatings

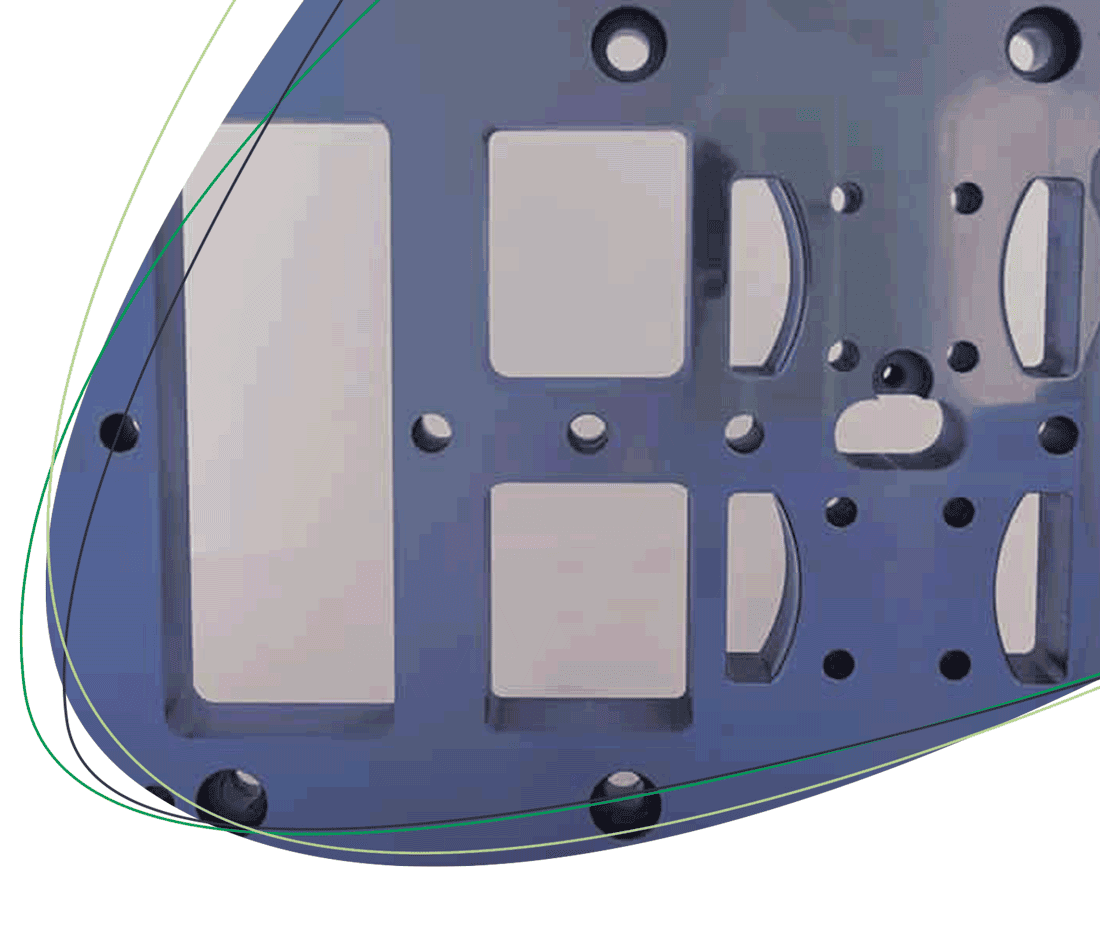

Titanium carbonitride (TiCN)

An ingenious combination, a powerful combination: the interplay of titanium nitride and carbon in a multilayer coating impresses with extreme hardness and minimized friction.

Layer by layer by layer … to success

TiN + C = TiCN. Titanium nitride and carbon alternately layered on top of each other. The multilayer titanium carbonitride coating has the structure of a lasagna. The carbon makes the layer even harder and smoother – which further reduces the coefficient of friction and improves the sliding properties. The tendency to cold welding is also significantly reduced.

The coating is regarded as a further development of TiN and is very popular for punching in steel processing, as it leads to a further improvement in tool life. The multilayer structure minimizes the residual stresses in the layer and, in combination with an additional sliding coating (TopCoat), the stripping forces can also be reduced when punching stainless steel.

TiCN can be selectively decoated quickly and easily.

Specifications Titanium carbonitride (TiCN)

Colour | bluish silver |

Hardness | 3.000 HV |

Coating thickness | 2 – 5 µm depending on use and wear type |

Coating temperature | 200 – 500 °C |

Coefficient of friction against steel | 0,38 |

Thermal oxidation resistance | 400 – 500 °C |

Decoatability | of all steel qualities and carbide |

Areas of application | Punching, forming, bending, embossing |

Individual coating services: Let us advise you!

Do you already know what you need? Or do you need more information? We have been developing PVD coatings for our customers for over 30 years and are sure to have the right coating solution for your individual application. We also guarantee a fast delivery time! Put your trust in our experience!