Applications

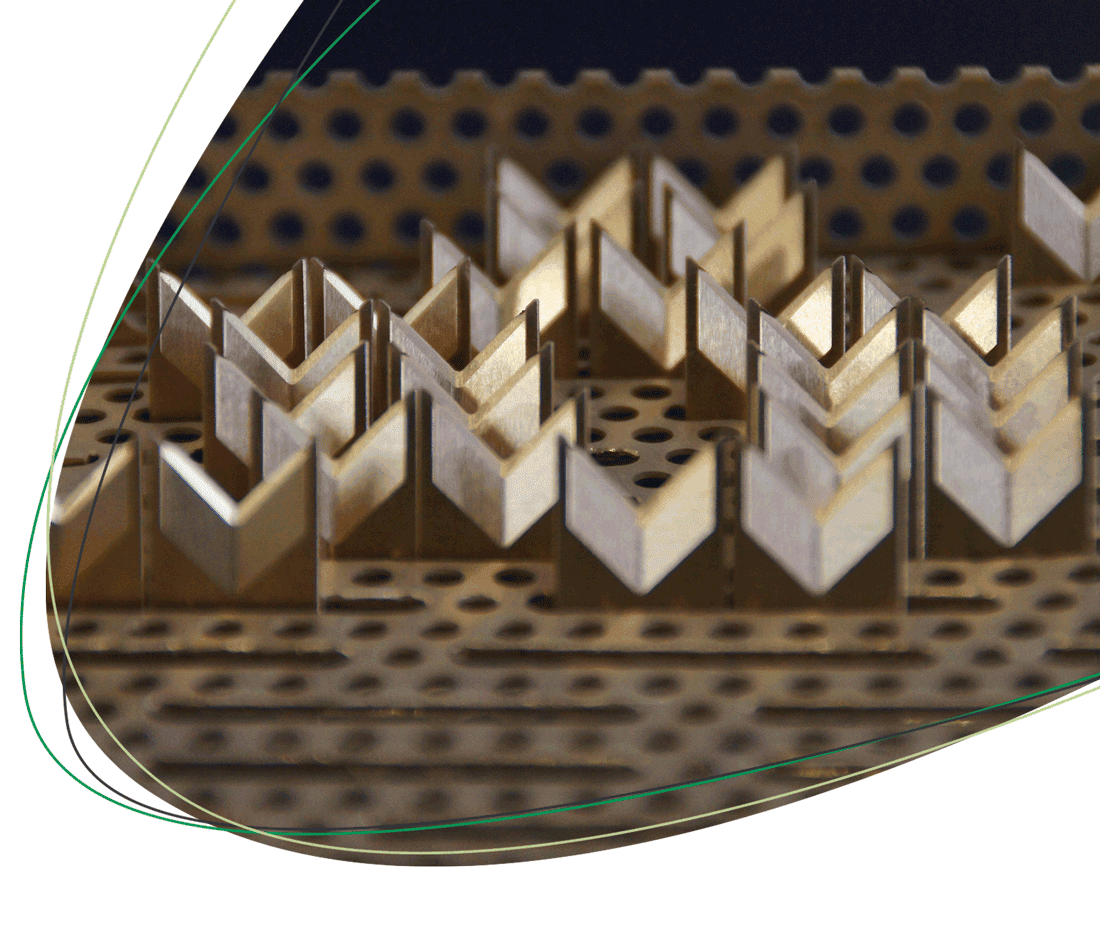

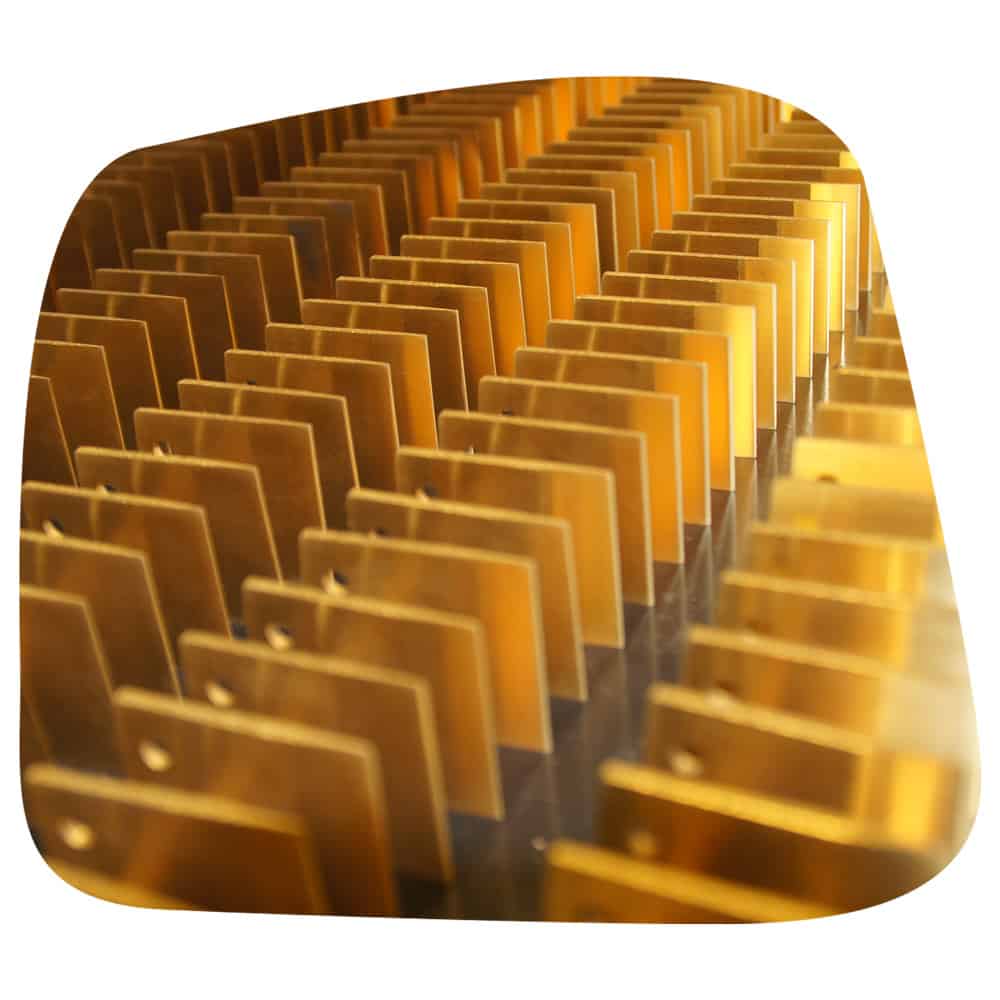

Blades

GPA-coated blades are characterized by lower cutting forces, reduced tendency to stick and less wear – they therefore cut through the material faster and for longer.

Full-surface coating and selective cutting edge coating

Depending on the application, industrial blades are coated either completely or only on the cutting edge.

Blade properties

The strength and hardness of the blade material are not impaired by a coating.

Wear reduction

Due to the high hardness of the PVD coatings, coated blades wear less quickly than uncoated blades: blade life is increased.

Corrosion protection

The chemically inert coating protects the blade surface against chemical and corrosive attacks within certain limits.

Increased cutting speeds

With a low coefficient of friction and high hardness, coated blades glide better through the material and enable higher productivity.

Dust reduction

Cutting with coated blades produces less dust due to the cleaner cutting surfaces.

Reduced tendency to stick

Coated blades glide better through sticky materials due to the lower coefficient of friction. In this case, the entire blade is usually coated to prevent build-up on the blade flanks.

Reduced cutting forces

The lower coefficient of friction leads to a reduction in cutting forces.

Reduced unit costs

The increase in blade service life and cutting speeds with simultaneous reduction in cutting resistance leads to improved productivity and shorter set-up times.

Individual coating services: Let us advise you!

Do you already know what you need? Or do you need more information? We have been developing PVD coatings for our customers for over 30 years and are sure to have the right coating solution for your individual application. We also guarantee a fast delivery time! Put your trust in our experience!