Applications

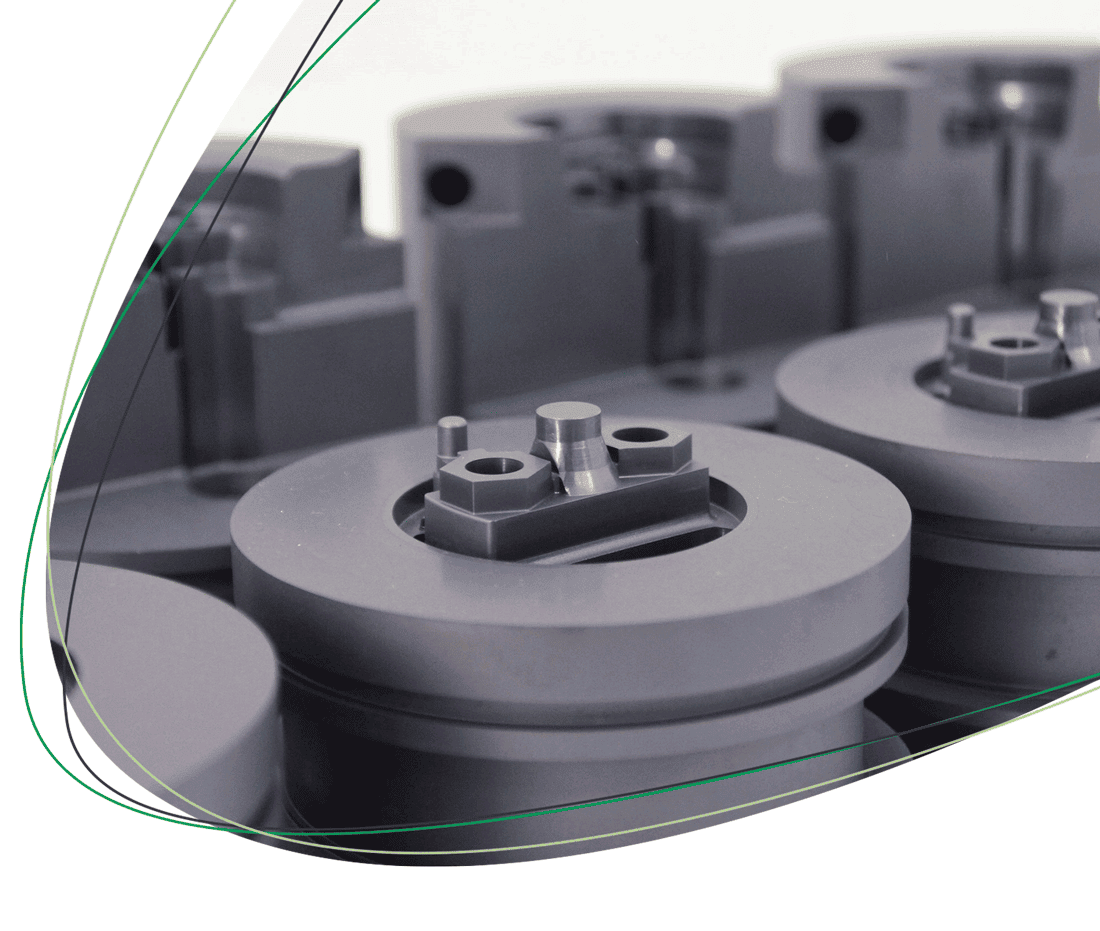

Plastics technology

A PVD coating extends the tool life. Especially when plastics with a high proportion of abrasive components need to be processed. Coated forming tools exhibit better operating behavior.

More even mold filling

The coating ensures better mold filling, as the melt remains flowable for longer. Sink marks are minimized by longer effective holding pressure.

Lower demolding forces

Demolding is made easier by reducing the plastic’s tendency to stick. In many cases, release agents can be dispensed with completely.

Better quality of the molded parts

Thanks to better mold filling, less warpage and more brilliant surfaces, higher quality parts can be produced and waste can be reduced.

Greater wear resistance

In the case of abrasive melting, wear is massively reduced by the high hardness of the coating. The coating also protects against damage during maintenance work and cleaning.

Good wear indicator

Color changes on the coated surface make it possible to detect wear in good time and to rework the cost-intensive forming tools at an early stage.

Optimized dry-running properties

Thanks to the low coefficient of friction, moving mold parts (e.g. ejectors, guide elements, boring cores, sliders, etc.) are better and more effectively protected against seizing. Release agents can be reduced or eliminated completely.

Easier cleaning

Mold deposits only form after a much higher number of shots and can be removed with simple means. Longer cleaning intervals and faster cleaning increase the availability of the tools.

Higher productivity

Significantly longer service lives, shorter cycle times and the improved operating performance of coated molds increase productivity in injection molding and reduce unit costs.

Good wear indicator

Color changes on the coated surface make it possible to detect wear in good time and to rework the cost-intensive forming tools at an early stage.

Optimized dry-running properties

Thanks to the low coefficient of friction, moving mold parts (e.g. ejectors, guide elements, boring cores, sliders, etc.) are better and more effectively protected against seizing. Release agents can be reduced or eliminated completely.

Easier cleaning

Mold deposits only form after a much higher number of shots and can be removed with simple means. Longer cleaning intervals and faster cleaning increase the availability of the tools.

Higher productivity

Significantly longer service lives, shorter cycle times and the improved operating performance of coated molds increase productivity in injection molding and reduce unit costs.

Individual coating services: Let us advise you!

Do you already know what you need? Or do you need more information? We have been developing PVD coatings for our customers for over 30 years and are sure to have the right coating solution for your individual application. We also guarantee a fast delivery time! Put your trust in our experience!