Applications

Punching and fine blanking

The use of a GPA coating gives your punching tools the finishing touch. The specific objectives are to extend tool life with an increased number of strokes and improved part quality.

The economic benefits are manifold:

Improve service life

The high hardness of the GPA coatings effectively protects the punch and die against wear – extending tool life.

Increase edge protection

The coating of your punching tools results in a hard surface, which in turn reduces the tendency for edge chipping on the punch and die.

Reduce cold welding

Cold welding can occur in the die, especially during fine blanking, due to small cutting gaps. The right coating reduces this tendency.

Improve surface quality

The PVD coating increases the cutting durability of the punches. The low coefficient of friction increases the proportion of cut surface compared to the proportion of torn surface.

This reduces burrs and tear marks in the finished part and improves quality.

Reduce scraper forces

When punching high-strength materials such as stainless steel, there is a risk of the punches being torn off due to the stripping forces.

A PVD coating reduces friction in the tool and thus the risk of tearing.

Reduce lubricant

Thanks to the low coefficient of friction of the GPA-PVD coating, the use of lubricants can be reduced in many cases without affecting the quality of the finished part or tool wear.

Improve demolding

The low coefficient of friction and the lack of chemical affinity to the workpiece improve the ejection of the finished part. Tool breakage due to jamming is prevented.

Reduce unit costs

The longer tool life in conjunction with higher stroke rates leads to a higher output quantity per tool, which reduces unit costs.

Specifications Punching and fine blanking

Material | Usable PDV coatings | Recommendation | Optimisation |

Unalloyed steel | TiN, TiCN, AlCro-Protect

| TiCN | Polishing + TopCoat |

Steel < 500 N/mm2 | TiN, TiCN, AlCro-Protect

| TiCN

| Polishing + TopCoat |

Steel > 500 N/mm2 | TiN, TiCN, AlCro-Protect

| TiCN

| Polishing + TopCoat |

Stainless steel | TiN, TiCN, AlCro-Protect

| TiCN + TopCoat

| Polishing |

Galvanised sheet steel | CrN, S-Protect, B-Protect

| S-Protect + TopCoat

| Polishing |

Aluminium alloys | CrN, B-Protect, DLC-Protect

| CrN + TopCoat

| Polishing |

Titanium alloys | B-Protect

| B-Protect + TopCoat

| Polishing |

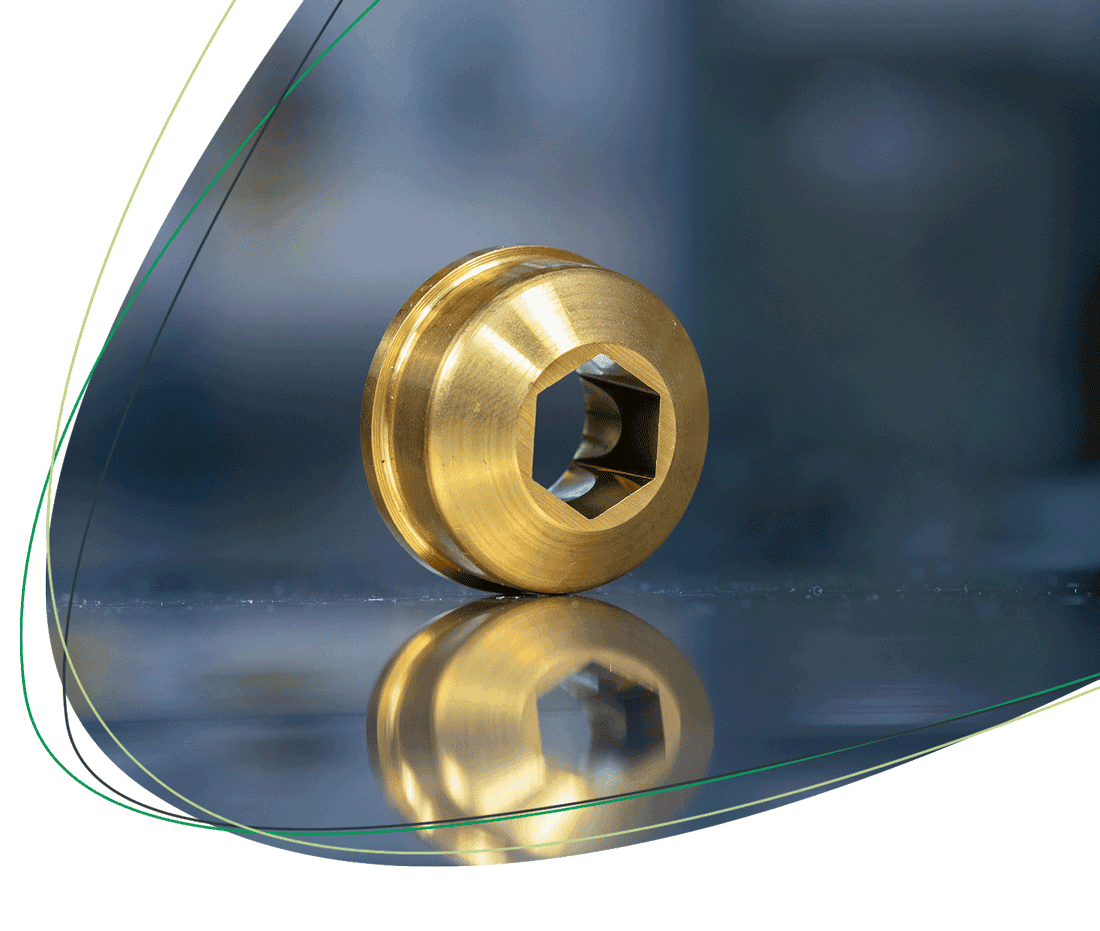

Copper, brass, bronze | B-Protect, AlCro-Protect

| B-Protect + TopCoat

| Polishing |

Individual coating services: Let us advise you!

Do you already know what you need? Or do you need more information? We have been developing PVD coatings for our customers for over 30 years and are sure to have the right coating solution for your individual application. We also guarantee a fast delivery time! Put your trust in our experience!