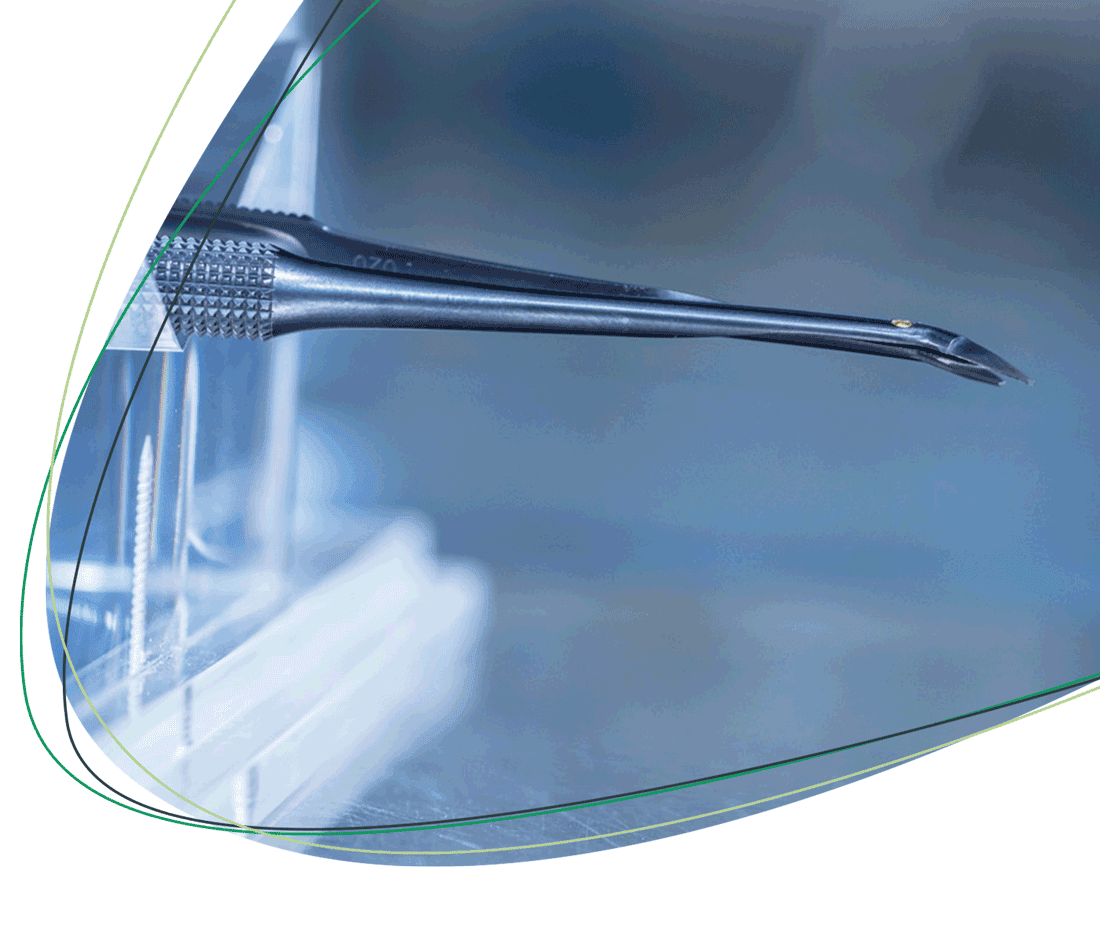

PVD coatings

B-Protect® (AlTiN)

B-Protect® – the premium combination of aluminum and titanium nitride: Convinces with up to 300 °C higher hot hardness resistance compared to the TiN coating and proves itself as a hard material coating for demanding tasks.

AlTiN: Tool protection at it’s best

We don’t want to have the most layers on offer for our customers, but the best. And we actually only want to offer our customers a single coating for their tools: the most suitable one! B-Protect® – our combination of aluminum and titanium nitride – is often one of them.

Even more durable than TiCN or TiN, this multilayer coating has excellent properties for machining steel. Friction, which occurs at higher cutting speeds, generates heat that can destroy tools. The extreme hardness of the coating in combination with oxidation resistance at temperatures of up to 800/900 °C enables demanding machining operations.

The B-Protect® coating can also be used for minimum quantity lubrication and dry machining. The emergency running properties of highly stressed components are improved.

And in plastics processing? B-Protect® offers wear protection against abrasive fillers and improves demoldability.

An example of success? With pleasure. Textured door handles: They are sprayed with abrasive media such as glass or metal fibers, and the high speed of injection causes washouts. Thanks to the hardness of the coating and the good demolding properties, the customer was able to increase the service life by 300%.

Because B-Protect® is a multi-layer coating, it provides a good wear indicator: if the golden titanium nitride layer shimmers through, this is a sign that the coating will soon be worn off. However, it can be selectively decoated and recoated quickly and easily.

Specifications B-Protect® (AlTiN)

Colour | dark purple to black |

Hardness | ca. 3.300 HV |

Coating thickness | 2 – 5 µm depending on use and wear type |

Coating temperature | 200 – 500 °C |

Coefficient of friction against steel | 0,37 |

Thermal oxidation resistance | 800 – 900 °C |

Decoatability | of all steel qualities and carbide |

Anwendungsbereiche | All machining operations, plastic injection moulding, forming, fine blanking |

Individual coating services: Let us advise you!

Do you already know what you need? Or do you need more information? We have been developing PVD coatings for our customers for over 30 years and are sure to have the right coating solution for your individual application. We also guarantee a fast delivery time! Put your trust in our experience!